Services

Hot rolling mills

Niagara Specialty Metals operates two versatile hot-rolling mills capable of reducing a wide variety of metals to thicknesses ranging from 0.025 to 4 inches. Whether you need a single piece or a 10,000+-pound order, our mills are designed for flexibility to meet your specific requirements. Hot rolling is performed using either gas or electric furnaces, depending on the metal and the desired properties. This process not only improves the workability of metals like stainless steel, tool steel, and titanium, but also ensures uniform thickness and enhanced structural integrity, making it ideal for industries such as aerospace, defense, and construction.

Key Benefits:

- Flexible hot-rolling capabilities for both small and large orders

- Customizable hot-rolling processes using gas or electric furnaces

- Suitable for a wide range of metals and alloys

Sheet & Plate Flattening

Our flattening services ensure that metal sheets and plates meet precise tolerances, regardless of the material’s thickness or composition. Using hydraulic roller levelers and high-powered presses, we can flatten metals such as titanium, molybdenum, and other specialty alloys with unparalleled precision. This process is especially important for applications requiring flat, stable materials, including aerospace, medical devices, and manufacturing. With quick turnaround times and the ability to flatten customer-supplied materials, our flattening services ensure that your products are fully prepared for subsequent fabrication or assembly.

Key Benefits:

- Precision flattening for titanium, molybdenum, and other specialty alloys

- Hydraulic roller levelers provide superior flatness and consistency

- Quick turnaround, including for customer-supplied materials

Cutting Services – Metal Sawing & Shearing

Niagara Specialty Metals provides precision cutting services engineered to meet exact customer specifications. Equipped with advanced shears, saws, and plasma cutting technology, we cut a wide range of materials—including high-strength steels, tool steels, and specialty alloys—with accuracy and efficiency. Whether working with thin or heavy-gauge metals, our processes deliver smooth, clean edges while minimizing material waste. Our cut-to-size sheets, strips, and complex profiles help manufacturers streamline production and accelerate time to market across aerospace, defense, and industrial applications. For projects requiring specialized geometries or tighter tolerances, we offer fully customized cutting solutions tailored to your unique requirements.

Key Benefits:

- Precision cutting with minimal material waste

- Custom cut-to-size solutions for diverse industries

- Capable of processing high-strength steels and specialty alloys

- Reduced lead times and simplified purchasing workflows

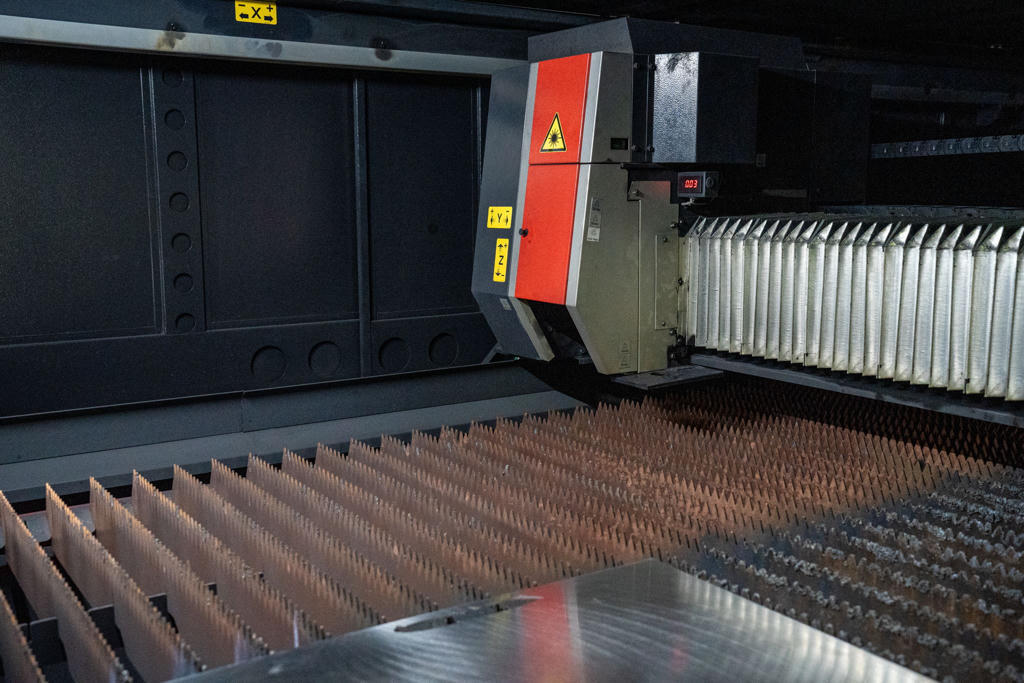

Cutting Services - Laser & Waterjet

We offer extensive specialty cutting capabilities, utilizing the latest in CNC technology. Our 4kW CNC laser and two abrasive water jets can cut virtually any material up to 4 inches thick, providing precision and repeatability for every project. We also have a network of seventeen horizontal and vertical band saws capable of cutting plates up to 28 inches thick and 13 feet long. These cutting services are designed to meet the most demanding specifications, ensuring high accuracy with a tolerance of +.063 to -.000 inches. Whether you need rapid sheet shearing for sheets or intricate, production-ready CNC cuts from computer-generated drawings, we can accommodate your needs with fast turnaround times and reliable results.

Key Benefits:

- Advanced CNC laser and water jet cutting for precision parts

- High-capacity band saws for thick plates and long lengths

- Consistent accuracy and repeatability ensured through CNC-operated machines

Annealing Services

At Niagara Specialty Metals, we offer advanced annealing services to enhance the physical and mechanical properties of your materials. Our controlled annealing process heats metals to precise temperatures and cools them gradually to relieve internal stresses, increase ductility, and improve machinability. We work with a wide range of specialty metals - including tool steels, stainless steels, and nickel-based alloys - to optimize their performance for downstream manufacturing. This service is essential for industries that rely on high-performance materials, such as aerospace, defense, and energy sectors.

Key Benefits:

- Stress relief and improved machinability

- Enhanced ductility for easier forming and processing

- Suitable for a wide range of specialty metals and alloys

Grinding Services

NSM offers precision grinding services engineered to achieve tight tolerances and exceptionally smooth surface finishes on specialty metals. Using state-of-the-art grinding equipment, we provide surface grinding that meets the demanding standards of industries such as aerospace, medical device manufacturing, and tool and die making. Our capabilities ensure flat, uniform surfaces on sheets, plates, and specialty parts — delivering materials that are fully production-ready. Whether your project requires fine surface finishes or close-tolerance dimensions, our grinding services provide consistent, reliable, and repeatable results.

Key Benefits:

- Precision grinding for extremely tight tolerances

- Fine surface finishes on specialty metals

- Ideal for aerospace, medical devices, and tool manufacturing

Blanchard Grinding

Our Blanchard grinding services offer fast and efficient stock removal for large surface areas. Known for its “signature cross-hatch” pattern, Blanchard grinding is ideal for achieving uniform, rough surface finishes on large metal plates, castings, and mold bases. Niagara Specialty Metals uses high-capacity Blanchard grinders to achieve high stock removal rates, making this service perfect for preparing materials for further machining. Whether you’re working with tool steels or other specialty alloys, our Blanchard grinding ensures consistently flat surfaces across your metal products.

Key Benefits:

- High stock removal for large surface areas

- Fast, efficient grinding with uniform, reliable results

- Ideal for preparing metals for further machining

Metal Descaling

We provide top-tier descaling services for both sheets and plates, using advanced techniques like shot blasting with stainless steel cut-wire or sandblasting with aluminum oxide. Descaling is a critical step in removing mill scale, oxide, and other surface impurities that can affect the performance and appearance of metals. Whether you are working with stainless steel, titanium, or tool steels, our descaling process ensures that your materials are clean and ready for further processing. By utilizing multiple blasting mediums, we can customize the descaling process to suit a variety of materials, ensuring optimal surface preparation for painting, coating, or bonding.

Key Benefits:

- Effective removal of mill scale and surface impurities

- Customized descaling process for different materials

- Prepares metals for further treatment such as painting or coating

Conversion Services

Niagara Specialty Metals offers comprehensive conversion services for mill distributors, OEMs, and end-users, providing expert shearing, rolling, cutting, precision flattening, and annealing of alloys, tool steels, and aerospace-grade metals. Our advanced equipment and skilled personnel allow us to handle a wide range of conversion projects efficiently and cost-effectively. Whether you need flat-rolled sheets or plates processed to specific tolerances, our conversion services are designed to meet the high standards required in industries such as aerospace, defense, and manufacturing. We pride ourselves on offering rapid turnaround times and competitive pricing without compromising on quality.

Key Benefits:

- Full-service conversion services for alloys and tool steels

- Cost-effective solutions for mill distributors and OEMs

- Precision processing of flat-rolled sheets and plates