CPM® 10V® (AISI A11)

DATA SHEET

Typical Composition

| C | Mn | Si | Cr | Mo | V |

|---|---|---|---|---|---|

| 2.45 | 0.50 | 0.90 | 5.25 | 1.30 | 9.75 |

CPM® 10V® was the first in the family of high vanadium tool steels made by the Crucible® Particle Metallurgy process. Crucible® engineers optimized the vanadium content to provide superior wear resistance while maintaining toughness and fabrication characteristics comparable to D2 and M2. Since its introduction in 1978, CPM® 10V® has become recognized world-wide and sets the standard for highly wear resistant industrial tooling. Its exceptional wear resistance and good toughness make it an excellent candidate to replace carbide and other highly wear resistant materials in cold work tooling applications, particularly where tool toughness is a problem or where cost effectiveness can be demonstrated.

The CPM® process produces very homogeneous, high quality steel characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional processes.

Machinability and Grindability- Machinability in the annealed condition is similar to T15 high speed steel. Similar grinding equipment and practices used for high speed steels are recommended. “SG” type alumina wheels or CBN wheels have generally given the best performance with CPM® steels.

CPM® Steel

Conventional Steel

Mechanical Properties

Impact Toughness- Depending upon the application requirement for hardness, lowering the hardening temperature (under hardening) increases the toughness

| Hardening Temperature | Tempering Temp. | HRC | Charpy C-Notch Strength | Bend Fracture Strength | ||||

|---|---|---|---|---|---|---|---|---|

| F | (C) | F | (C) | Ft.-lb. | (J) | Ksi | (Mpa) | |

| 2150 | 1175 | 1000 | 540 | 64 | 15 | 20 | 627 | 4322 |

| 2100 | 1150 | 1000 | 540 | 63 | 16 | 22 | 615 | 4239 |

| 2050 | 1120 | 1025 | 550 | 61 | 23 | 30 | 635 | 4377 |

| 1950 | 1065 | 1025 | 550 | 59 | 26 | 35 | ||

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Critical Temperature: 1540°F (840°C).

Forging: 2000-2100°F (1095-1150°), do not forge below 1700°F (930°C). Slow Cool.

Annealing: Heat to 1600°F (870°C), hold 2 hours, slow cool no faster than 30°F (15°C) per hour to 1000°F (540°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: About BHN 255-277.

Stress Relieving

Annealed Parts: Heat to 1100-1300°F (595-700°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 30°F (15°C), below original tempering temperature, hold 2 hours, then furnace cool or cool in still air.

Straightening: Best done warm 400-800°F (200-430°C).

Hardening

Preheat: Heat to 1500-1550°F (815-845°C), Equalize. Second pre-heat stage at 1850-1900°F (1010-1040°C) suggested for vacuum or atmosphere hardening.

Austenitize: 1850-2150°F (1010-1175°C), hold time at temperature 30-45 minutes.

Quench: Air or positive pressure quench (2 bar minimum) to below 125°F (50°C), or salt or interrupted oil quench to about 1000°F (540°C), then air cool to below 125°F (50°C). Salt bath treatment, if practical, will ensure maximum attainable toughness for a given hardening treatment. Vacuum or atmosphere quench rate through 1850-1300°F (1010-705°C) range is critical to achieve optimum heat treat response.

Temper: Double temper at 1000°F (540°C) minimum. 2 hours minimum each time.

Size Change: +0.03/0.05%.

Recommended Heat Treatment: For the best combination of toughness and wear resistance, austenitize CPM® 10V® at 2050°F (1120°C), hold 30-45 minutes, and quench. Temper 3 times at 1025°F (550°C).

Aim hardness: HRC 60. Higher austenitizing temperatures can be used to obtain higher hardness, at a slight decrease in impact resistance. The lower austenitizing temperatures provide the best impact toughness.

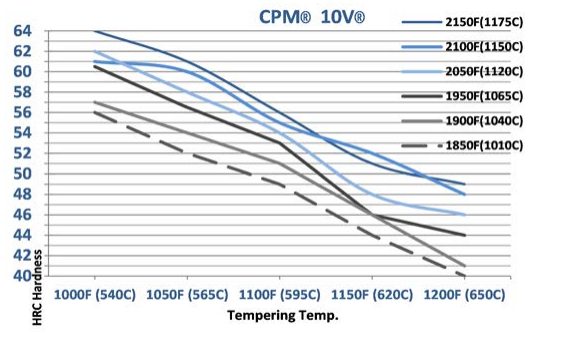

Heat Treat Response (HRC Hardness)

Austenitizing Temperature

| Tempering Temp. | 1850°F (1010°C) | 1900°F (1040°C) | 1950°F (1065°C) | 2050°F (1120°C) | 2100°F (1150°C) | 2150°F (1175°C) |

|---|---|---|---|---|---|---|

| As Quenched | 61 | 63 | 65 | 65 | 64.5 | 63.5 |

| 1000°F (540°C) | 56 | 57 | 60.5 | 62 | 63 | 64 |

| Optimum for Maximum Toughness and Effective Stress Relieving | ||||||

| 1025°F (550°C) | 54 | 56 | 58.5 | 60 | 62 | 63 |

| 1050°F (565°C) | 52 | 54 | 56.5 | 58 | 60 | 61 |

| 1100°F (595°C) | 49 | 51 | 52 | 54 | 55 | 56 |

| 1150°F (620°C) | 44 | 45 | 46 | 48 | 50 | 51 |

| 1200°F (650°C) | 40 | 41 | 43 | 46 | 47 | 48 |

| Results can vary with the use of the hardening method and its section size. You will get the best result with Salt or Oil quenching. Vacuum or atmosphere cooling may result in up to 1-2 HRC points lower. | ||||||

| Minimum Time at Aust. Temp. | 60 min. | 45 min. | 30 min. | 20 min. | 15 min. | 10 min. |

| Minimum Number Tempers | 2 | 2 | 2 | 2 | 3 | 3 |

Surface Treatments

Because of its high tempering temperatures (>1000°F) CPM® 10V® is suitable for nitriding, PVD coating or similar surface treatments. CVD coating processes generally exceed the critical temperature and may result in non-predictable dimensional changes.

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001