CPM® 15V®

DATA SHEET

Typical Composition

| C | Mn | Si | Cr | Mo | V |

|---|---|---|---|---|---|

| 3.40 | 0.50 | 0.90 | 5.25 | 1.30 | 14.50 |

CPM® 15V® is intended for applications requiring exceptional wear resistance. It has more vanadium carbides in its microstructure than CPM® 10V® and provides more wear resistance and longer tool life in those applications where 10V® has proven to be successful. CPM® 15V® also offers an alternative to solid carbide where carbide fails by fracture or where intricate tool design makes carbide difficult or risky to fabricate.

The CPM® process produces very homogeneous, high quality steel characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional processes.

The typical applications of CPM® 15V® include Powder Compactions Tooling: Dies and Core Rods, Plastic processing Equipment: Barrel Lines and Screw Tips, Industrial Knives: Granulator Blades, Slitter Knives, and Dies/Punches for Cold Work (Forming, Extrusion, Drawing, and Piercing), Woodworking Tools, Ceramic Dies, and Wear Parts.

CPM® Steel

Conventional Steel

Wear Resistance

With it’s nearly 15% vanadium content, CPM® 15V® has the highest wear resistance of any cold work tool steel available today.

Impact Toughness

The CPM® process makes possible the production of high vanadium grades without sacrificing toughness. For example, although both CPM® 10V® and CPM® 15V® have significantly higher wear resistance than the conventional high vanadium tool steel D7, they also offer greater toughness.

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Critical Temperature: 1540°F (838°C).

Forging: 2000-2100°F (1095-1150°C) Do not forge below 1700°F (930°C). Slow cool.

Annealing: Heat to 1600°F (870°C), hold 2 hours. Slow cool no faster than 30°F (15°C) per hour to 1000°F (540°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: About BHN 255-277.

Stress Relieving

Annealed Parts: Heat to 1100-1300°F (595-705°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 25-50°F (15-30°C) below original tempering temperature, hold 2 hours, then furnace color cool in still air.

Hardening

Preheat: Heat to 1500-1550°F (815-845°C), Equalize. A second pre-heat stage at 1850-1900°F (1010-1040°C) is suggested for vacuum or atmosphere hardening.

Austenitize: 1950-2150°F (1065-1175°C), hold time at temperature 20-30 minutes.

Quench: Air or positive pressure quench (2 bar minimum) to below 125°F (50°C), or salt or interrupted oil quench to about 1000°F (540°C), then air cool to below 125°F (50°C). Salt bath treatment, if practical, will ensure the maximum attainable toughness for a given hardening treatment.

Temper: Two times at 1000°F (540°C), 2 hrs. minimum each time. Temper three times for hardening temperatures over 2100°F (1150°C).

Size Change: +0.04/0.05%.

Recommended Heat Treatment: For maximum wear resistance, austenitize at 2150°F (1175°C), hold 10 minutes, and quench. Temper 3 times at 1025°F (550°C).

Aim hardness: HRC 61-63.

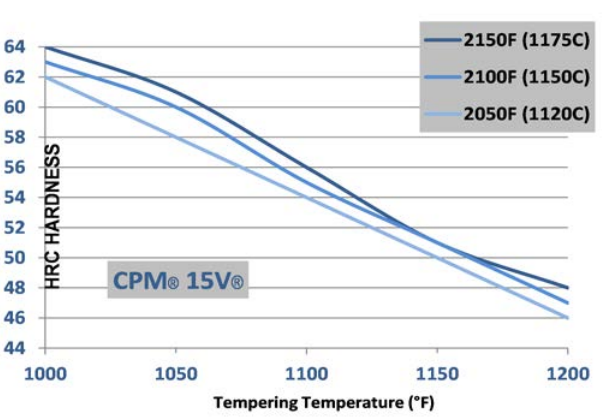

Heat Treat Response (HRC Hardness)

Austenitizing Temperature

| Austenitizing Temperature | |||

|---|---|---|---|

| Tempering Temp. | 2050°F (1120°C) | 2100°F (1150°C) | 2150°F (1175°C) |

| Minimum Time | 30 Min. | 20 Min. | 10 Min. |

| 1000°F (540°C) | 62 | 63 | 64 |

| Optimum Time and Temp to be Effective | |||

| 1025°F (550°C) | 60 | 62 | 63 |

| 1050°F (565°C) | 58 | 60 | 61 |

| 1100°F (595°C) | 54 | 55 | 56 |

| 1150°F (620°C) | 48 | 50 | 51 |

| 1200°F (650°C) | 46 | 47 | 48 |

| Minimum Tempers | 2 | 2 | 3 |

Results may vary with hardening method and section size. Salt or oil quenching will give maximum response. Vacuum or atmosphere cooling may result in up to 1-2 HRC points

lower.

Surface Treatments

Because of its high tempering temperatures (>1000°F) CPM® 15V® is suitable for nitriding, PVD coating or similar surface treatments. CVD coating processes generally exceed the critical temperature and may result in non-predictable dimensional changes.

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001