CPM® 1V®

DATA SHEET

Typical Composition

| C | Mn | Si | Cr | W | Mo | V |

|---|---|---|---|---|---|---|

| 0.55 | 0.40 | 0.50 | 4.50 | 2.15 | 2.75 | 1.00 |

CPM® 1V® is a medium carbon, high alloy tool steel which exhibits high toughness combined with high heat resistance. It is suited for both hot or cold applications which demand high impact toughness and also require moderate wear resistance.

The CPM® process produces very homogeneous, high quality steel characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional processes.

The Typical Hot (Warm) Work applications include Hot and Warm Forming Die, Hot Shear Dies, Hot Heading Dies, Extrusion Dies, and Forging Dies and Punches.

The Typical Cold Work applications include Cold Heading Dies, High Impact Blanking Dies, Punches, and Thread Rolling Dies.

*Note: These are some typical applications. Your specific application should not be undertaken without independent study and evaluation.

CPM® Steel

Conventional Steel

Relative Mechanical Properties

Impact Toughness and Wear Resistance- With its 1% vanadium content, CPM® 1V® has wear resistance slightly better than A2. Because of its CPM® microstructure, 1V® has high impact toughness approaching that of the shock resistant tool steels such as S7.

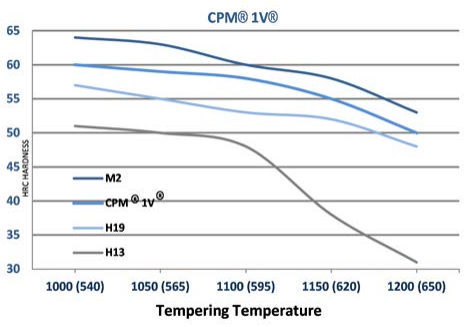

Temper Resistance

Because of its high alloy composition, CPM® 1V® has temper resistance similar to high speed steel (M2) and much better than most typical hot work tool steels as shown in the comparative temper curves below.

Machinability and Grindability

The machinability and grindability of CPM® 1V® in the annealed condition is similar to that of A2.

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Annealing

Heat to 1600-1650°F (870-900°C), hold 2 hours, slow cool no faster than 25°F (15°C) per hour to 1100°F (595°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: About BHN 187.

Stress Relieving

Annealed Parts: Heat to 1100-1300°F (595-705°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 25-50°F (15-30°C) below original tempering temperature, hold 2 hours, then furnace cool or cool in still air.

Hardening

Preheat: Heat to 1550-1600°F (840-870°C), Equalize.

Austenitize: 1950-2000°F (1065-1120°C), hold time at temperature 10-15 minutes. The lower austenitizing temperature of 1950°F (1065°C) provides the best impact toughness.

Quench: Positive pressure quench (2 bar minimum) to below 125°F (50°C), or salt or interrupted oil quench to about 1000°F (540°C), then air cool to below 125°F (50°C). Salt bath treatment if practical will ensure maximum attainable toughness for a given hardening treatment.

Temper: Three times at 1000-1025°F (540-550°C), 2 hours minimum each time.

Aim hardness 57-59 HRC.

Surface Treatments

CPM® 1V® can be nitrided or PVD coated. Due to its high tempering temperature, it will retain its hardness after such processes, making it a more suitable substrate than A2 or S7. As for most tool steels, higher temperature surface treatments, such as CVD, may result in dimensional distortion.

Note: Properties shown throughout this data sheet are typical values. Normal variations in chemistry, size and heat treat conditions may cause deviations from these values.

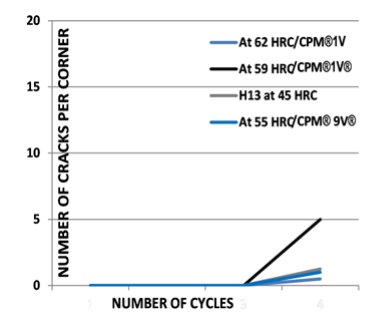

Thermal Fatigue

The results of thermal fatigue tests show that CPM® 1V® offers an improvement over premium quality H13 and CPM® 9V®. Thermal fatigue tests are used to predict performance in die casting or other applications involving cyclic high temperature exposures.

1.) Specimans were dipped in molten aluminum at 1250°F and water quenched. Every 5000 cycles specimens were microscopically examined for corner cracks

Heat Treatments of Specimens for Thermal Fatigue Tests

| HRC | Austenitize | Quench | Temper | |

|---|---|---|---|---|

| CPM® 1V® | 60 | 2000°F / 10 min | Air | 1000°F / 2 + 2 hrs. |

| CPM® 1V® | 59 | 1950°F / 30 min | Air | 1000°F / 2 + 2 hrs. |

| Premium H13 | 45 | 1875°F / 30 min | Oil | 1130°F / 2 + 2 hrs. |

| CPM® 9V® | 55 | 2050°F / 30 min | Air | 1000°F / 2 + 2 hrs. |

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001