CPM® 20CV

DATA SHEET

Typical Composition

| C | Cr | Mo | V | W |

|---|---|---|---|---|

| 1.9% | 20.0% | 1.0% | 4.0% | 0.6% |

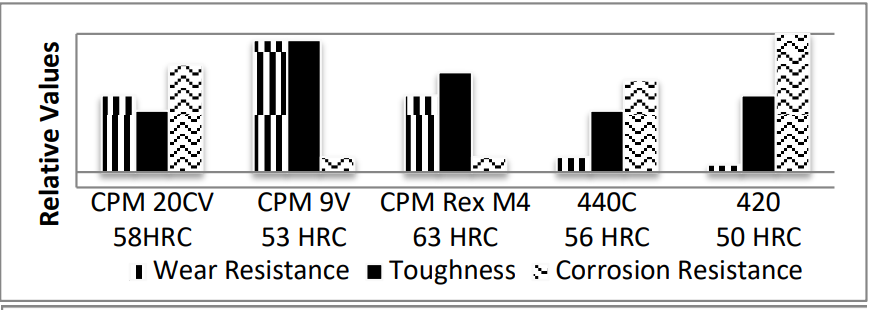

CPM® 20CV is a unique tool steel made by the Crucible Particle Metallurgy Process. It is a martensitic stainless steel with a high volume of vanadium carbides for exceptionally good wear resistance. CPM® 20CV contains the highest amount of chromium of any high-vanadium stainless steel currently available. The chromium rich matrix provides outstanding corrosion resistance. CPM® 20CV an excellent steel for plastic injection feed screws, barrel liners, screw tips and mold cavities, especially for plastic resins which contain abrasive fillers.

The CPM® process results in a finer, more uniform carbide distribution imparting improved toughness and grindability to highly alloyed steels. The CPM® process also alloys for the design of more highly alloyed grades which cannot be produced by conventional steelmaking.

Typical Applications: High performance, long-wearing specialty cutlery, plastic injection and extrusion feed screws and dies, granulator knives, pelletizing equipment, wear components for Food and Chemical Processing.

Edge Retention

(CATRA Test Relative to 440C)

| Grade | % |

|---|---|

| CPM® 20CV | 180 |

| 14-2-4 CrMoV | 145 |

| 14-4 CrMo | 120 |

| 440C | 100 |

The CATRA (Cutlery & Allied Research Association) test machine measures the total number of silica impregnated cardscut in a sequence of passes along the blade. It is considered a relative measure of edge retention and wear resistance.

Physical Properties

Density: 0.275 lb/in^3 (7616 kg/m^3)

Modulus of Elasticity: 31x10^6 psi (214 GPa)

Machinability: 35-40% of a 1% carbon steel

Coefficient of Thermal Expansion

| Temperature °F | in/in/°F x 10^-6 | Temperature °C | mm/mm/°C x 10^-6 |

|---|---|---|---|

| 68-212 | 6.06 | 20-100 | 10.9 |

| 68-392 | 6.23 | 20-200 | 11.2 |

| 68-572 | 6.56 | 20-300 | 11.8 |

| 68-752 | 6.73 | 20-400 | 12.1 |

| 68-932 | 6.84 | 20-500 | 12.3 |

CPM® Steel

Conventional Steel

Steel Comparagraph

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Annealing

Annealing must be performed after hot working and before rehardening. Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1860-1900°F (1016-1038°C), and hold at temperature for 1 hour per inch (25.4 mm) of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 30°F per hour (15°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be approximately 30 HRC or lower. Another option is subcritical anneal. Heat to 1450° and hold for 4 to 6 hours. Furnace cool 15°/hr to 1250°F, hold for 4 hours, then furnace cool until black (about 900°F) before pulling the hood.

Hardening

Preheat: Heat to 1400-1450°F (760-788°C) and equalize.

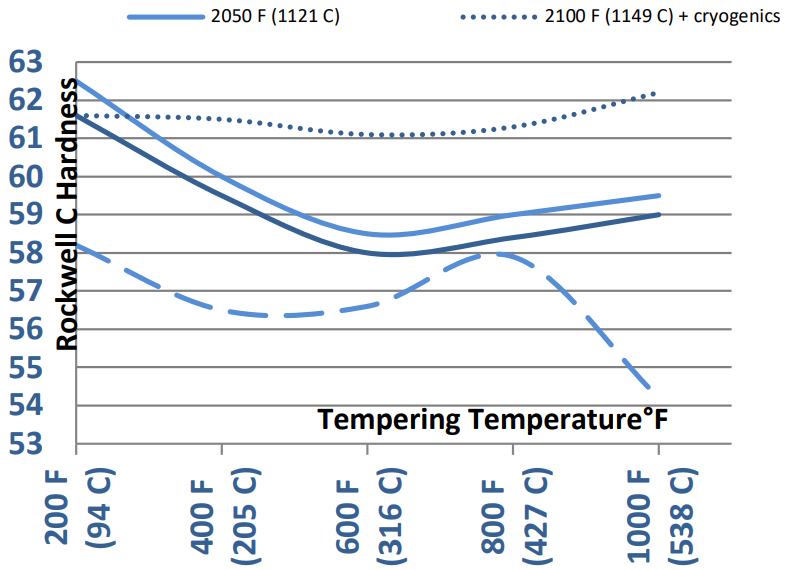

Austenitize: Heat rapidly from the preheat to a temperature to within 1960-2150°F (1071-1177°C). A lower austenitizing temperature will maximize impact toughness. A higher

austenitizing temperature will maximize wear resistance and corrosion resistance. Soak at the austenitizing temperature for 30 minutes. Austenitizing between 2050°F and 2150°F should be done in a vacuum furnace.

Quench: Pressurized gas or warm oil. For pressurized gas, the furnace should have a minimum quench pressure of 4 bars. A quench rate of approximately 400°F (222°C) per minute to below 1000°F (538°C) is critical to obtain the desired properties. For oil, quench until black, about 900°F (482°C), then cool in still air to 150-125°F (66-51°C).

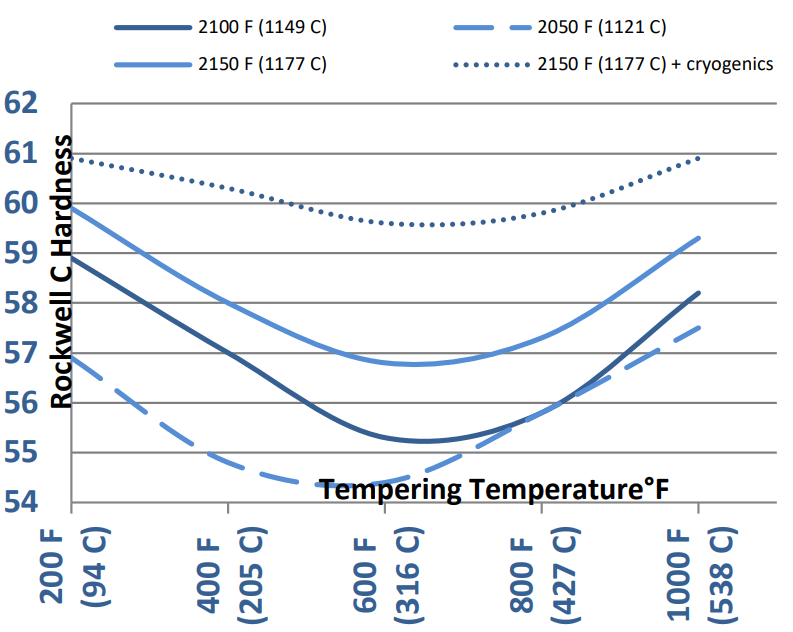

Temper: Temper immediately after quenching, or after quenching and cryogenic treatment. Typical temperature range is 400-800°F (204-427°C). Hold at temperature for 1 hour per inch (25.4mm) of thickness, 2 hours minimum, then air cool to ambient temperature. The typical service hardness is 56-59 HRC, although higher hardness may be used for increased wear resistance. Tempering between 800 and 1100°F (427-583°C) will decrease corrosion resistance and toughness.

Cryogenic Treating: For austenitizing at 2100°F (1149°C) or higher, a cryogenic treatment is recommended after quenching to 150 to 125°F (66-51°C) to reduce retained austenite. Cool to -100°F (-73°C), remove from the cooling medium, and allow part to warm to ambient temperature in still air.

Heat Treatment Response

For Furnace or Salt Bath Hardening:

Oil Quenched from

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001