CPM® REX® T15 HS (AISI T15)

DATA SHEET

Typical Composition

| C | Cr | W | V | Co | S |

|---|---|---|---|---|---|

| 1.60 | 4.00 | 12.00 | 4.90 | 5.00 | 0.06 (0.22)* |

*Because of the extremely fine and uniform microstructure produced by the CPM® process, sulfur may be added if desired to improve the machinability. The higher sulfur content benefits the toolmaker by allowing ease of manufacture and the tool user by allowing easier resharpening. The CPM® process ensures that the additional sulfur will not detrimentally affect the tool’s toughness.

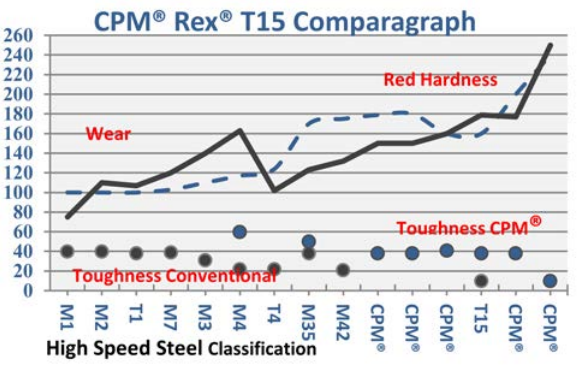

CPM® Rex® T15 (HS) is a super high speed steel made by the CPM® process. It is a tungsten type high speed containing high vanadium for excellent abrasion resistance, and cobalt for good red hardness. CPM® Rex® T15 is ideal for cutting difficult to machine materials where high frictional heating is encountered.

The CPM® process results in a homogeneous microstructure with a finer, more uniform carbide distribution imparting superior dimensional stability, grindability and toughness when compared to steels produced by conventional processes. The CPM® process also allows the design of more highly alloyed grades which cannot be produced by conventional steelmaking.

Machinability in the annealed condition is approximately 20% of W1 Tool Steel (1% C).

Grindability of CPM® Rex® T15 compares favorably with regular high speed steels because of the fine, uniformly distributed carbides. Conventional grinding wheels designed for high speed steels can be used. In special cases, the advice of a grinding wheel manufacturer should be sought.

The typical applications of CPM® Rex® T15 are broaches, end mills, form tools, gear hobs, milling cutters, spade drills, shape cutters, and taps.

(Note: these are some typical applications. Your specific application should not be undertaken without independent study and evaluation)

Conventional Steel

CPM® Steel

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Critical Temperature: 1550°F (845°C).

Forging: 2000-2100°F (1095-1150°C). Do not forge below 1700°F (925°C). Slow cool after forging.

Annealing

Heat to 1600°F (870°C), hold 2 hours, slow cool no faster than 25°F (15°C) per hour to 1000°F (540°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: Approx. BHN 245/275.

Stress Relieving

Annealed parts: Heat to 1100-1300°F (595-705°C), hold 2 hours, then air cool or furnace cool.

Hardened parts: Heat to 25°F (15°C) below original tempering temperature, or 1000°F (540°C) minimum, hold 2 hours, then air cool or furnace cool.

Straightening: Best done warm 400-800°F (200-430°C).

Hardening (Salt Bath or Vacuum Furnace preferred.)

Pre-heat: 1500-1550°F (815-845°C), hold long enough to soak through. A second pre-heat at 1850-1900°F (1010-1040°C) is recommended when vacuum hardening.

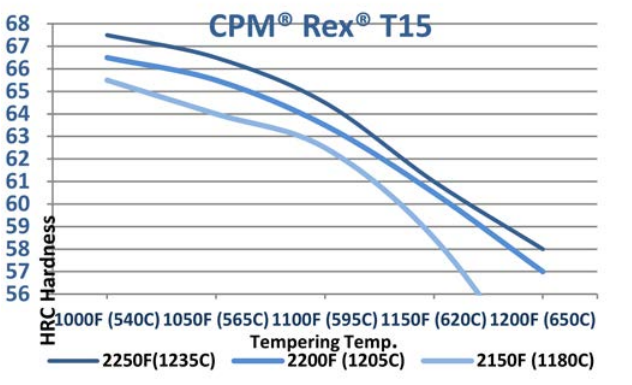

Austenitize: 2125-2250° F (1165-1235°C). To achieve HRC 66-68, 2225-2250°F (1220-1235°C) is recommended.

Quench: Salt, oil or atmosphere quench to below 1100°F (595°C) equalize then air cool to hand warm, below 125°F (50°C). Vacuum or atmosphere quenching may result in slightly lower hardness for larger tools. A fast quench rate from hardening temperature to below 1100°F (595°C) is critical to achieve optimum heat treat response. To minimize distortion, a slower cooling rate below 1000°F (540°C) may be used.

Temper: Triple temper at 1000°F (540°C) or higher. Hold at least 2 hours at temperature for each temper. Air cool to room temperature between tempers.

Size Change During Hardening (Longitudinal):

| Hardening Temp. | Tempering Temp. | HRC | Long. Size Change |

|---|---|---|---|

| 2200°F (1205°C) | 1025°F (550°C) | 66 |

+0.0020 in./in (+0.051 mm/mm) |

Heat Treat Response (HRC Hardness)

| Austenitizing Temperature | ||||||

|---|---|---|---|---|---|---|

| Tempering Temp. | 2125°F (1165°C) | 2150°F (1180°C) | 2175°F (1190°C) | 2200°F (1205°C) | 2225°F (1220°C) | 2250°F (1235°C) |

| As Quenched | 67 | 66.5 | 66 | 65.5 | 64.5 | 64 |

| 1000°F (540°C) | 65 | 65.5 | 66 | 66.5 | 67 | 67.5 |

| Optimum for Maximum Toughness and Effective Stress Relieving | ||||||

| 1025°F (550°C) | 64.5 | 65 | 65.5 | 66 | 66.5 | 67 |

| 1050°F (565°C) | 64 | 64.5 | 65 | 65.5 | 66 | 66.5 |

| 1100°F (595°C) | 62 | 62.5 | 63 | 63.5 | 64 | 64.5 |

| 1150°F (620°C) | 57 | 58.5 | 59.5 | 60.5 | 61 | 61.5 |

| 1200°F (650°C) | 54 | 55 | 56 | 57 | 57.5 | 58 |

| Results can vary with the use of the hardening method and its section size. You will get the best result with Salt or Oil quenching. Vacuum or atmosphere cooling may result in ≈1 HRC points lower. | ||||||

| Minimum Time at Aust. Temp. | 10 min | 10 min | 10 min | 5 min | 5 min | 5 min. |

| Minimum Number of Tempers | 3 | 3 | 3 | 3 | 3 | 3 |

Toughness: Lowering the hardening temperature reduces the grain size and increases toughness.

| Hardening Temp. °F (°C) |

Tempering Temp. °F (°C) |

Hardness HRC |

Charpy Impact C-Notch ft-lb (J) |

Bend Fracture Strength ksi (MPa) |

|---|---|---|---|---|

| 2250 (1235) | 1000 (540) | 68 | 12 (16) | 581 (4005) |

| 2250 (1235) | 1025 (550) | 67 | 14 (19) | 678 (4675) |

| 2150 (1175) | 1025 (550) | 65 | 21 (28) | 706 (4865) |

| 2150 (1175) | 1050 (565) | 64.5 | 22 (29) | 740 (5102) |

Surface Treatments

CPM® Rex® T15 can be nitrided or PVD coated if desired. If a CVD treatment is used, subsequent hardening is required and may result in undesirable distortion.

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001