CPM® S110V

DATA SHEET

Typical Composition

| C | Nb (Cb) | Co | Cr | Mo | V |

|---|---|---|---|---|---|

| 2.80 | 3.00 | 2.50 | 15.25 | 2.25 | 9.00 |

CPM® S110V is a high alloy martensitic stainless tool steel produced by the Crucible Particle Metallurgy (CPM®) process. CPM® S110V contains a high volume fraction of both vanadium-rich and niobium-rich primary alloy carbides for exceptionally good wear resistance compared to other commercially available PM tool steels. It also offers better corrosion resistance than 440C or CPM® S90V.

CPM® S110V is currently available on special request in the as-HIP condition or as a clad layer on components. It is also available in hot rolled decarb free sheet.

The CPM® process results in a fine and uniform carbide distribution in CPM® S110V compared to conventionally produced high alloy tool steels which results in relatively good machining, grinding, and toughness characteristics despite the high alloy content.

Typical Applications: As-HIP solid or clad components requiring a combination of high wear resistance and good corrosion resistance such as: Screw elements, barrel liners for compounding machines, industrial knives, high end cutlery, slitters and circular cutters, rolls and wear components for food and chemical processing applications.

CPM® S110V

AISI 440C

Machining and Grinding

Due to its carbide content and high annealed hardness, machining and grinding CPM® S110V will be more difficult than 440C (or D2), and comparable to or slightly more difficult than CPM® S90V. Grinding equipment and practices similar to those used for CPM® S90V are acceptable. SG type alumina wheels or CBN wheels are recommended for best performance with CPM® steels.

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Annealing

Heat to 1650°F (900°C), hold 2 hours, slow cool at a maximum rate of 25°F (15°C) per hour to 1100°F (595°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: Approximately 350-400 BHN.

Stress Relieving

Annealed Material: Heat to 1100-1300°F (595-705°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Material: Heat to 25-50°F (15-30°C) below original tempering temperature, hold 2 hours, then furnace cool or cool in still air.

Hardening

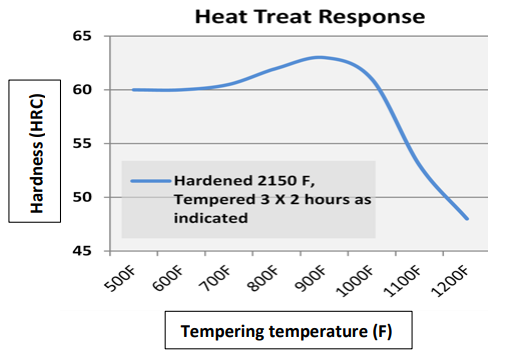

Austenitize: 2150°F (1175°C) Hold 20 minutes.

Quench: Salt quench, interrupted oil quench, positive pressure gas quench or air cool at a minimum cooling rate of 250°F/min (140°C/min) to below 1000°F (540°C). Cool to below 125°F (50°C) before tempering. For optimum vacuum heat treatment response, a minimum 4 bar gas quench is recommended.

Temper: Temper three times, minimum hold time 2 hours at temperature each temper. Cool completely to room temperature between tempers.

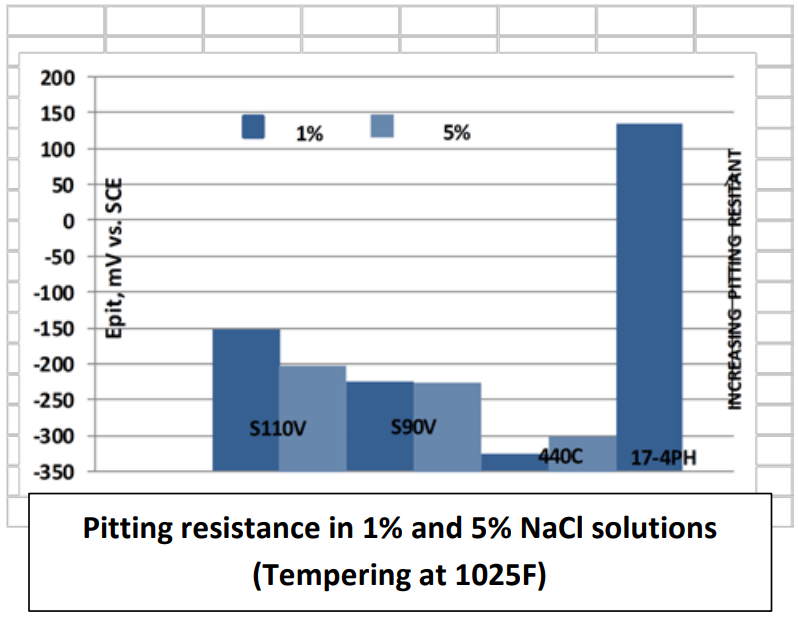

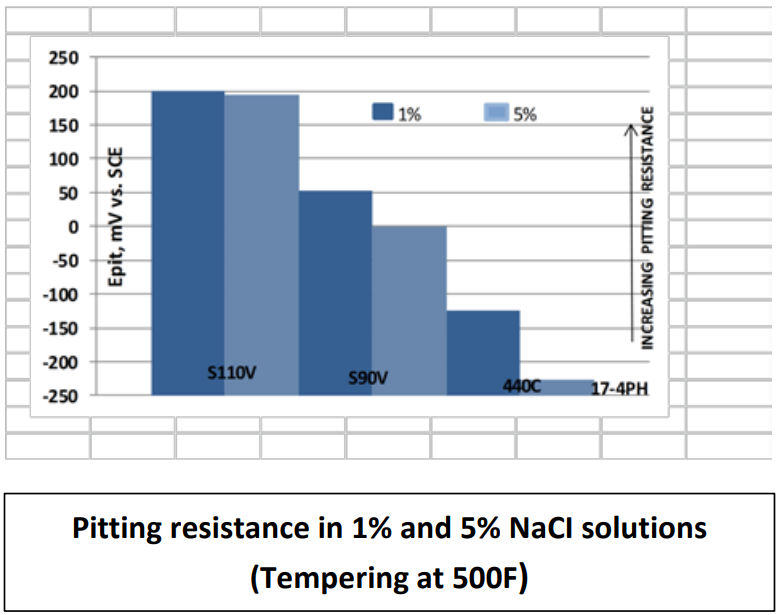

Tempering temperatures: 400-750°F (200-400°C): Best corrosion resistance 975-1000°F (525-540°C): Maximum hardness and compressive yield strength, reduced corrosion

resistance 1025-1050°F (550-565°C): Optimum for best stress relieving and dimensional stability.

Note: Tempering any martensitic stainless steel above 750°F (400°C) may reduce its corrosion resistance.

Deep freezing (optional): When tempering at or below 750°F (400°C), a freezing treatment may be used between the first and second tempers to reduce retained austenite and maximize hardness. Freezing treatments should always be followed by at least one temper.

Size Change: +0.03 to +0.05% for a fully martensitic microstructure. The presence of retained austenite may reduce the net growth.

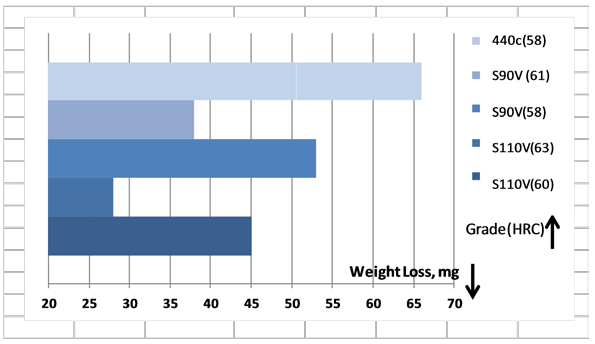

Typical Application Hardness: 58/61 HRC.

Wear Resistance

CPM® S110V features the same high vanadium content as CPM® S90V, plus the added contribution of 3.5% niobium, resulting in 25% greater volume of wear-resistant carbides, including 50% more of the wear-resistant MC type. The abrasive wear resistance of CPM® S110V at various hardnesses is compared to other wear-and corrosion-resistant grades below.

Corrosion Resistance

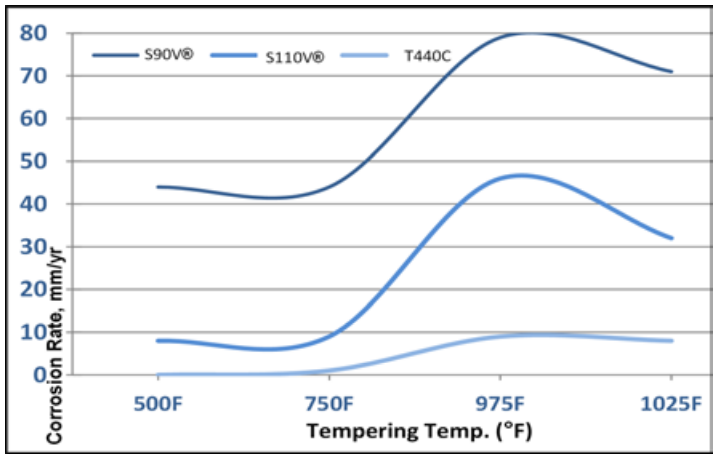

CPM® S110V displays enhanced corrosion resistance compared to other high hardness martensitic stainless tool steels such as 440C and CPM® S90V. Corrosion tests results in representative media are illustrated by the following laboratory test data.

Corrosion Rate in Dilute Aqua Regia (2.5% HN03+0.5% HCI+H20)

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001