CPM® S35VN

DATA SHEET

Typical Composition

| C | Nb | Cr | Mo | V |

|---|---|---|---|---|

| 1.40 | 0.50 | 14.00 | 2.00 | 3.00 |

CPM® S35VN is a martensitic stainless steel designed to offer improved toughness over CPM® S30V®. It is also easier to machine and polish than CPM® S30V®. Its chemistry has been rebalanced so that it forms some niobium carbides along with vanadium and chromium carbides. Substituting niobium carbides for some of the vanadium carbides makes CPM® S35VN about 15-20% tougher than CPM® S30V® without any loss of wear resistance. CPM® S35VN’s improved toughness gives it better resistance to edge chipping. Because both vanadium and niobium carbides are harder and more effective than chromium carbides in providing wear resistance, the CPM® stainless blade steels offer improved edge retention over conventional high chromium steels such as 440C and D2.

The CPM® process produces very homogeneous, high quality steel characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional melting practices.

The typical applications include: Long-wearing specialty cutlery, plastic injection and extrusion feed screws and dies, non-return valve components, pelletizing equipment, and wear components for food and chemical processing.

Cossorison Resistance

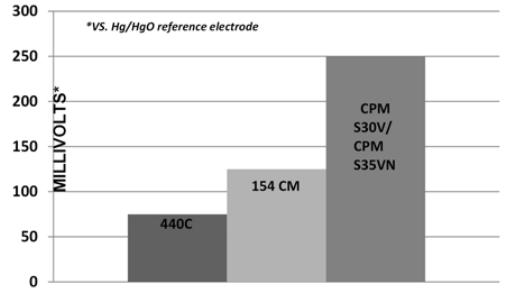

Average Pitting Potential measurements from Polarization Curves run in 5% NaCl (Sodium Chloride) Solution at Room Temperature: (Higher voltage pitting potential indicates better corrosion resistance).

Toughness

Although the longitudinal toughness of all four grades is 25-28 ft.lbs., the transverse toughness of the CPM® grades is four times more than 440C and 154 CM®. CPM® S35VN and CPM® S30V® are more resistant to chipping or breaking in applications with side loading and are better for bigger blades.

| Grade | Impact Energy |

|---|---|

| CPM® S35VN | 12.0 ft.lbs |

| CPM® S30V® | 10.0 ft.lbs |

| 154 CM® | 2.5 ft.lbs |

| 440C | 2.5 ft.lbs |

Edge Retention

The CATRA test is considered a measure of relative wear resistance compared to 440C, in the table.

| Grade | % |

|---|---|

| CPM® S35VN | 145* |

| CPM® S30V® | 145 |

| 154 CM® | 120 |

| 440C | 100 |

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Forging: 2100°F (1150°C) Do not forge below 1750°F (950°C).

Annealing: Heat to 1650°F (900°C), hold 2 hours, slow cool no faster than 25°F (15°C) per hour to 1100°F (595°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: About BHN 255.

Stress Relieving

Annealed Parts: Heat to 1100-1300°F (595-705°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 25-50°F (15-30°C) below original tempering temperature, hold 2 hours, then furnace cool or cool in still air.

Straightening: Best done warm 400-800°F (200-425°C).

Hardening

Preheat: Heat to 1550-1600°F (845-870°C), Equalize.

Austenitize: 1900-2000°F (1035-1095°C), hold time at temperature 15-30 minutes.

Quench: Air or positive pressure quench (2 bar minimum) to below 125°F (50°C), or salt or interrupted oil quench to about 1000°F (540°C), then air cool to below 125°F (50°C).

Temper: Double temper at 400-750°F (200-400°C). Hold for 2 hours minimum each time. A freezing treatment may be used between the first and second tempers. Freezing treatments help to attain maximum hardenability and must always be followed by at least one temper.

NOTE: For optimum stress relieving, CPM® S35VN may be tempered at 1000-1025°F (540-550°C). Tempering in this range may result in a slight decrease in corrosion resistance.

Size Change: +0.05 to +0.10% when fully martensitic. The presence of retained austenite may reduce the net growth. When tempering at 400-750°F (200-400°C), freezing treatments may be necessary to minimize retained austenite.

Recommended Heat Treatment

Austenitize 1950°F (1065°C). Quench to below 125°F (50°C). Double temper at 600°F (315°C) 2 hrs. minimum each temper. Cool to hand warm between tempers. A freezing treatment may be added between tempers.

Aim hardness: 58-61 HRC.

Carbide Type and Volume

| Vanadium | Niobium | Chromium | Total | |

|---|---|---|---|---|

| CPM® S35VN | 3.0% | 0.5% | 10.5% | 14.0% |

| CPM® S30V® | 4.0% | 10.5% | 14.5% | |

| 440C | 0% | 12.0% | 12.0% | |

| 154 CM® | 0% | 17.5% | 17.5% | |

| CPM® S90V | 9.0% | 11.0% | 20.0% |

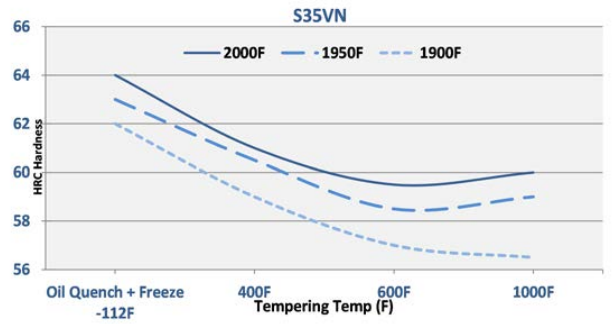

Heat Treat Response- Hardness (HRC)

| Austenitizing Temperature | ||||||

|---|---|---|---|---|---|---|

| 1900°F (1040°C) | 1950°F (1065°C) | 2000°F (1095°C) | ||||

| Tempering Temperature | Oil | Oil & Freeze -112°F | Oil | Oil & Freeze -112°F | Oil | Oil & Freeze -112°F |

| As Quenched | 60.5 | 62 | 62 | 63 | 63.5 | 64 |

| 400°F (200°C) | 57.5 | 59 | 57.5 | 60.5 | 59.5 | 61 |

| 600°F (315°C) | 57.5 | 57 | 59 | 58.5 | 59 | 59.5 |

| 1000°F (540°C) | 57 | 56.5 | 59.5 | 59 | 58.5 | 60 |

| Results may vary with hardening method and section size. Salt or oil quenching will give maximum response. Vacuum or atmosphere cooling may result in up to 1–2 HRC points lower. | ||||||

| Minimum Time at Austenitizing Temperature | 30 min. | 30 min. | 15 min. | |||

| Minimum Number of Tempers | 2 | 2 | 2 | |||

Machinability and Grindability

In the annealed condition, CPM® S35VN is much easier to machine than CPM® S90V and easier to machine than CPM® S30V®. Similar grinding equipment and practices used for high speed steels are recommended. “SG” type alumina wheels or CBN wheels have generally given the best performance with CPM® steels.

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001