CPM® S60V

DATA SHEET

Typical Composition

| C | Cr | Mo | V |

|---|---|---|---|

| 2.15 | 17.00 | 0.40 | 5.50 |

CPM® S60V is a corrosion resistant, highly wear-resistant steel made by the Crucible Particle Metallurgy process. It is a martensitic stainless steel with a high volume of chromium and vanadium carbides for exceptionally good wear and corrosion resistance. S60V offers substantial improvements in wear resistance over 440C and D2, and other high chromium tool steels, with corrosion resistance much better than 440C.

The CPM® process results in a finer, more uniform carbide distribution imparting improved toughness and grind ability to high alloy steels. The CPM® process also allows the design of more highly alloyed grades which cannot be produced by conventional steelmaking.

Typical Applications: Plastic injection and extrusion feed screws, non-return valve components, pelletizing equipment, gate and nozzle inserts, industrial knives, slitters, and cutters, long-wearing specialty cutlery, injection molds and inserts, wear components for food and chemical processing, bearings, bushings, valves, rolls and gear pumps.

Special Note to Knifemakers: The recommended hardness for blades is HRC 56/58, which is designed to provide an excellent combination of corrosion resistance, wear resistance and edge toughness.

Conventional Steel

CPM® Steel

Mechanical Properties

| Hardness (1) | Impact Toughness ft-lbs | ||

|---|---|---|---|

| HRC | Heat Treatment | ||

| CPM® S60V | 56 | (A) | 16 |

| CPM® S60V | 59 | (B) | 12 |

| CPM® S60V | 60.5 | (C) | 11 |

1.) A=Hardened 1850°F (1010°C), double tempered 400°F (205°C).

B=Hardened 1950°F (1065°C), double tempered 400°F (205°C).

C=Hardened 2050°F (1120°C), double tempered 400°F (205°C).

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

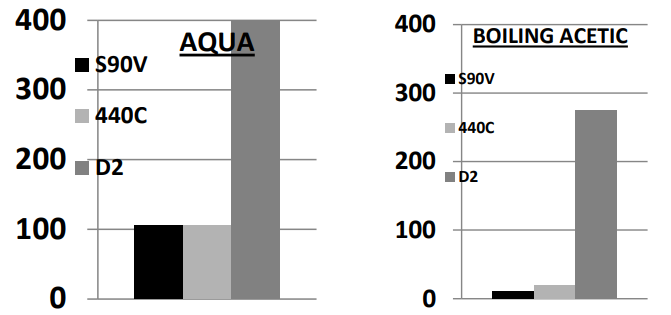

Corrosion Resistance

Corrosion tests measure the amount of material lost to corrosion. Therefore, lower numbers indicate better corrosion resistance.

Corrosion Test Results (1) in mm/year

| Boiling 10% Acetic (2) | Dilute Aqua- Regia (3) | |

|---|---|---|

| CPM® S90V | 9/17 | 102/117 |

| 440C | 29 | 109 |

| D2 | 267 | 411 |

Notes:

(1) Lower numbers indicate better corrosion resistance. All grades heat treated to about HRC 56/58. Corrosion resistance depends strongly on heat treated condition and specific environment. Results should be used as a qualitative comparison only.

(2) 24 hrs.

(3) 5% HNO3-1% HCI (nitric + hydrochloric acids) at 24°C.

Relative Corrosion Rates

(Lower numbers indicate better corrosion resistance)

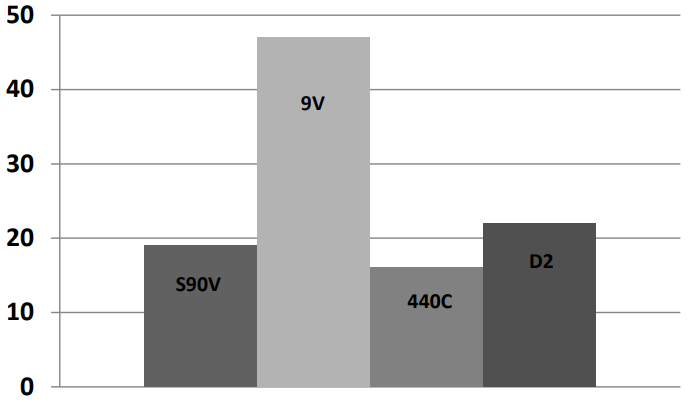

Impact Toughness

CPM® S90V offers higher impact toughness than 440C at comparable hardnesses.

Thermal Treatments

Annealing

Heat to 1650°F (900°C), hold 2 hours, slow cool at a maximum rate of 25°F (15°C) per hour to 1100°F (595°C), then furnace cool or cool in still air to room temperature.

Annealed Hardness: Approx. BHN 277.

Stress Relieving

Annealed Parts: Heat to 1100-1300°F (595-705°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 25-50°F (15-30°C) below original tempering temperature, hold 2 hours, then furnace cool or cool in still air.

Hardening

Austenitize: 2100-2150°F (1150-1175°C), hold time at temperature: 20 minutes.

Quench: Salt quench, interrupted oil quench, positive pressure gas quench or air cool at a minimum cooling rate of 150°F/min (80°C/min) to below 1000°F (540°C). Cool to below 125°F (50° C) before tempering. For optimum vacuum heat treatment response, a minimum 4 bar gas quench is recommended.

Temper: Double temper at 400-750°F (200-400°C). Hold for a minimum of 2 hrs. each temper. For optimum stress relieving and dimensional stability, S90V may be double tempered at 1000-1025°F (540-550°C), but tempering above 800°F (425°C) may result in some loss of corrosion resistance. A freezing treatment may be employed between the first and second tempers, if desired. Freezing treatments should always be followed by at least one temper.

PLEASE NOTE: Tempering between about 800 and 1000°F (425 and 540°C) is not recommended. All martensitic stainless steels suffer from embrittlement when tempered in this range.

Tempering Temperature

| 400°F – 800°F | Best corrosion resistance & wear resistance |

| 800°F – 1000°F | AVOID THIS RANGE (Embrittlement) |

| 1000°F – 1025°F | Stress relieving and dimensional stability |

Aim Hardness: HRC 56/59.

Size Change: +0.03 to +0.05%.

Size change shown is for a fully martensitic microstructure. The presence of retained austenite may reduce the net growth. When tempering at 400-750°F (200-400°C), freezing treatments may be necessary to minimize retained austenite.

Machinability and Grindability

Due to its high vanadium carbide content, the machinability and grindability of S90V will be slightly more difficult than that of D2 or 440C. Similar grinding equipment and practices are acceptable. SG type alumina wheels or CBN wheels have generally given the best performance with the CPM® steels.

Niagara Specialty Metals | 12600 Clarence Center Road, Akron, NY 14001