Specialty Metals by Industry - Cutlery & Knife Steel

Niagara Specialty Metals supplies premium metals engineered specifically for the hand cutlery industry. Our materials are selected for exceptional edge retention, hardness, toughness, and corrosion resistance—qualities essential for producing high-performance knives and cutting tools. From advanced stainless grades to high-alloy specialty steels, our portfolio supports the creation of durable, razor-sharp blades trusted by professional chefs, outdoor enthusiasts, and skilled makers alike. With rigorous quality standards and precision processing, we deliver metals that elevate the performance, longevity, and craftsmanship of hand-built cutlery.

| Grade | Category | Parts |

|---|---|---|

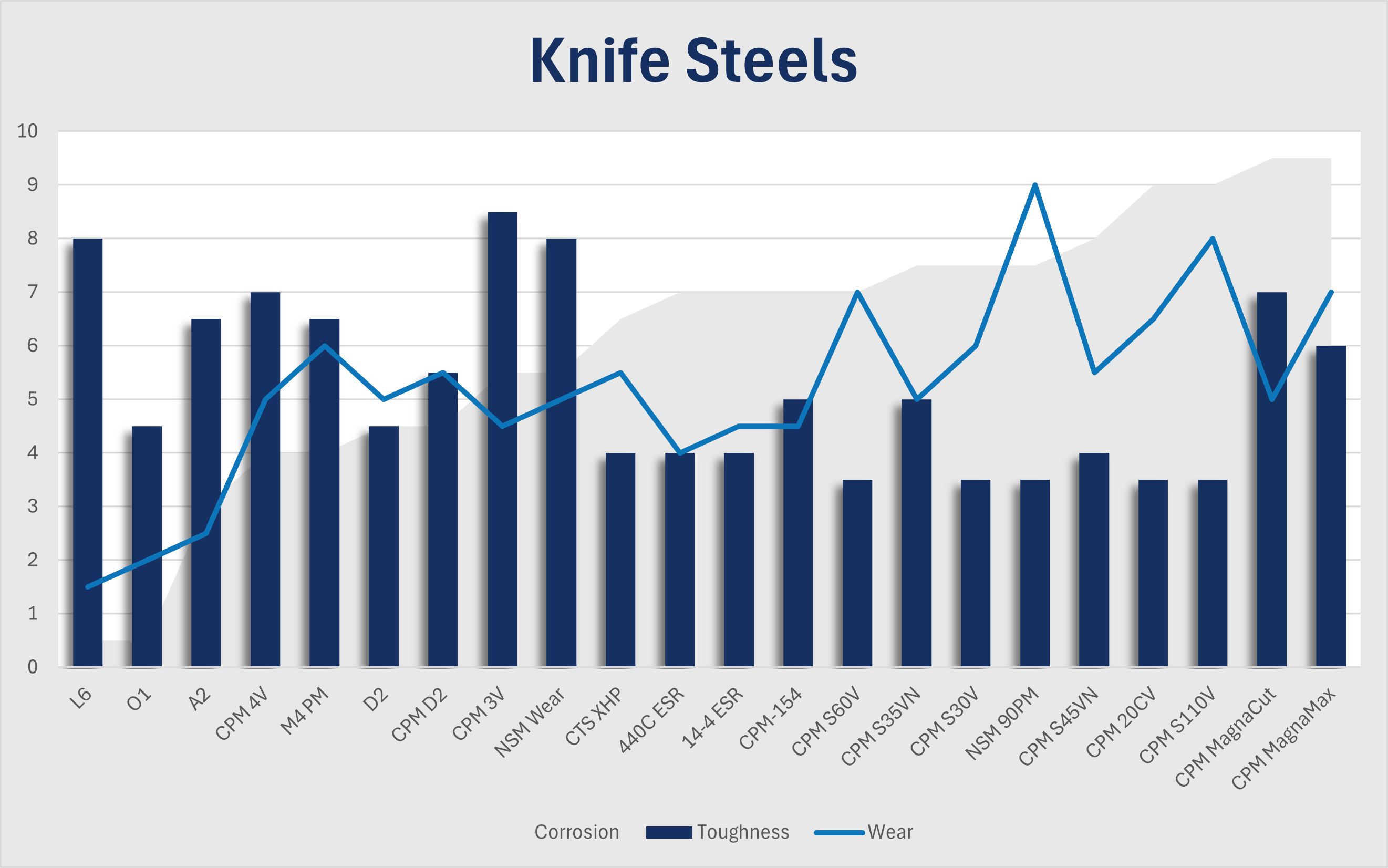

| CPM® 154, CPM® D2, CPM® S30V, CPM® S35VN, CPM® S45VN, CPM® S90V, CPM® MagnaCut®, CPM® 3V, CPM® 4V, and CPM® M4 | CPM® alloys for hand cutlery | Our CPM® cutlery alloys have various combinations of toughness, wear, and corrosion resistance. CPM® 3V is our toughest grade, CPM® S90V has the highest wear resistance. CPM® MagnaCut® has the highest corrosion resistance. Refer to our cutlery chart to see the combinations available to you. |

| 154CM, 440C ESR, and D2 | Air melt - lower cost alloys for hand cutlery | Our airmelt cutlery grade have a long history or high performance in the knife industry. They are more affordable for the everyday knife enthusiast. |

We supply three grades of wrought martensitic stainless steel and eight CPM® stainless grades for the cutlery industry—all proudly manufactured in the USA.

Wrought Stainless Steels

Our wrought stainless grades are widely used for knife blades and precision components.

416 Stainless – Commonly used in the specialty knife industry for bolsters, guards, and pins due to its excellent machinability.

440-C ESR – A popular blade material known for high hardness and wear resistance. Our 440-C undergoes Electroslag Remelting (ESR), an additional melting process that removes impurities and inclusions to produce a cleaner, higher-quality ingot.

154-CM – A performance upgrade to 440-C offering improved wear resistance and corrosion performance, making it a preferred choice for premium cutting tools.

CPM® Stainless Steels

Our CPM® (Crucible Particle Metallurgy) grades deliver enhanced performance over traditional wrought steels. The CPM® process eliminates alloy segregation and produces a uniform, fine microstructure with evenly distributed carbides. This results in superior toughness, improved edge stability, enhanced wear resistance, and greater flexibility in alloy design due to higher allowable alloy content.

The CPM® process also enables premium upgrades of existing alloys, as demonstrated by the development of CPM® 154.

Our two newest CPM® offerings—S45VN and MagnaCut®—represent the latest advancements in cutlery steel technology.

S45VN, designed by Frank Cox at Niagara Specialty Metals, provides increased corrosion resistance and wear performance compared to S30V and S35VN. This grade has already been adopted by multiple production knife manufacturers.

MagnaCut® delivers a highly optimized balance of toughness, hardness, and exceptional corrosion resistance, making it one of the most advanced stainless cutlery steels available today.