Specialty Metals by Industry - Industrial Metal Grades

At Niagara Specialty Metals, we provide top-quality metals engineered to withstand the rigorous demands of industrial applications. Our product range includes stainless, tool, and high-speed steels, all of which are essential for producing components that require exceptional strength, durability, and resistance to harsh operating conditions.

Powder Metallurgy (PM) Steel: High-Performance Alloys for Precision Applications

The specialty steels historically known as Crucible Particle Metallurgy (CPM®) grades have long been valued for their exceptional mechanical properties, ultra-clean microstructure, and reliable performance in critical applications. While Crucible Industries has ceased operations, the legacy of CPM® steels continues through new industry partnerships and sources.

Niagara Specialty Metals now sources premium powder metallurgy (PM) steels from Carpenter Technology and Erasteel, the latter of which has acquired the rights to the CPM® trademark. As a result, we are able to continue offering key CPM® branded steels through Erasteel, while also introducing new rebranded designations for grades we source from both mills. This approach ensures continued supply, consistent quality, and full transparency for our customers.

Key Benefits of PM Steel

- Increased Wear Resistance: Powder metallurgy reduces impurities and segregation, producing a more uniform carbide structure. This results in higher hardness and excellent wear resistance—ideal for cutting tools, dies, and high-use industrial parts..

- High Toughness and Strength: These steels offer a superior balance of toughness and tensile strength, performing reliably under high stress, impact, and other extreme conditions.

- Enhanced Machinability and Heat-Treatment Response: PM steels allow for tighter tolerances and finer finishes. They also respond well to a wide range of heat treatments for tailored hardness and performance.

- Corrosion Resistance: Select stainless PM grades (such as MagnaCut®, CPM® S30V, and CPM® 154) deliver outstanding corrosion resistance in aggressive environments.

Applications of PM Steel

- Cutting Tools and Knives: PM steels are widely used in high-end knives and industrial cutting tools for their superior edge retention and toughness.

- Molds and Dies: Cold-work and high-speed tool steels made via PM are preferred for applications requiring dimensional stability under load.

- Aerospace Components: The strength, fatigue resistance, and wear characteristics of PM steels make them a smart choice for critical structural parts in demanding environments.

Notable PM Tool Steel Grades

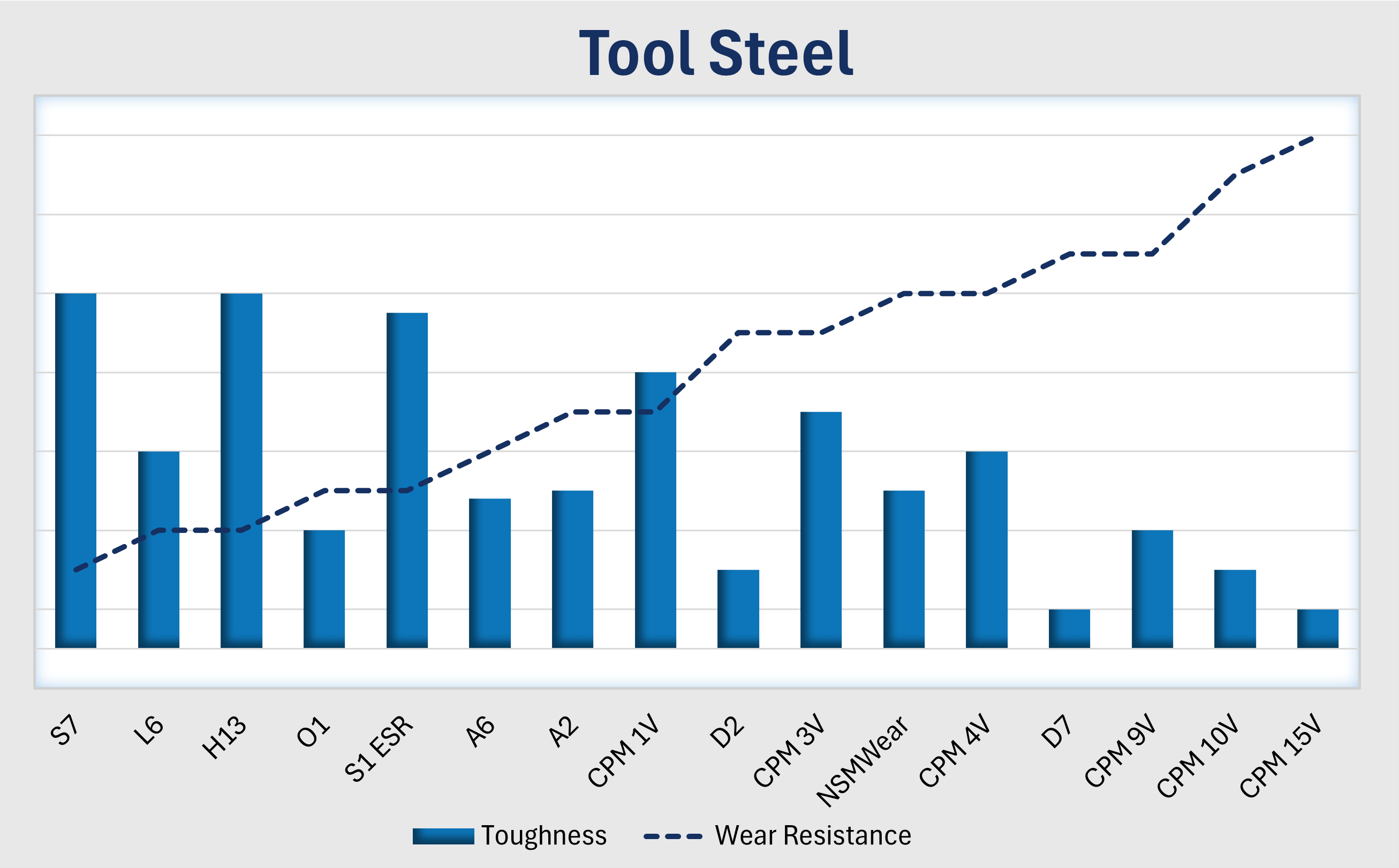

- CPM® 1V, CPM® 3V, and D2 (PM): Balancing toughness and wear resistance, these grades are popular across a range of tooling and forming applications.

- CPM® 9V and CPM® 10V: Designed for extreme wear resistance; CPM® 9V offers greater toughness, while CPM® 10V provides up to quadruple the wear resistance of D2 at comparable toughness.

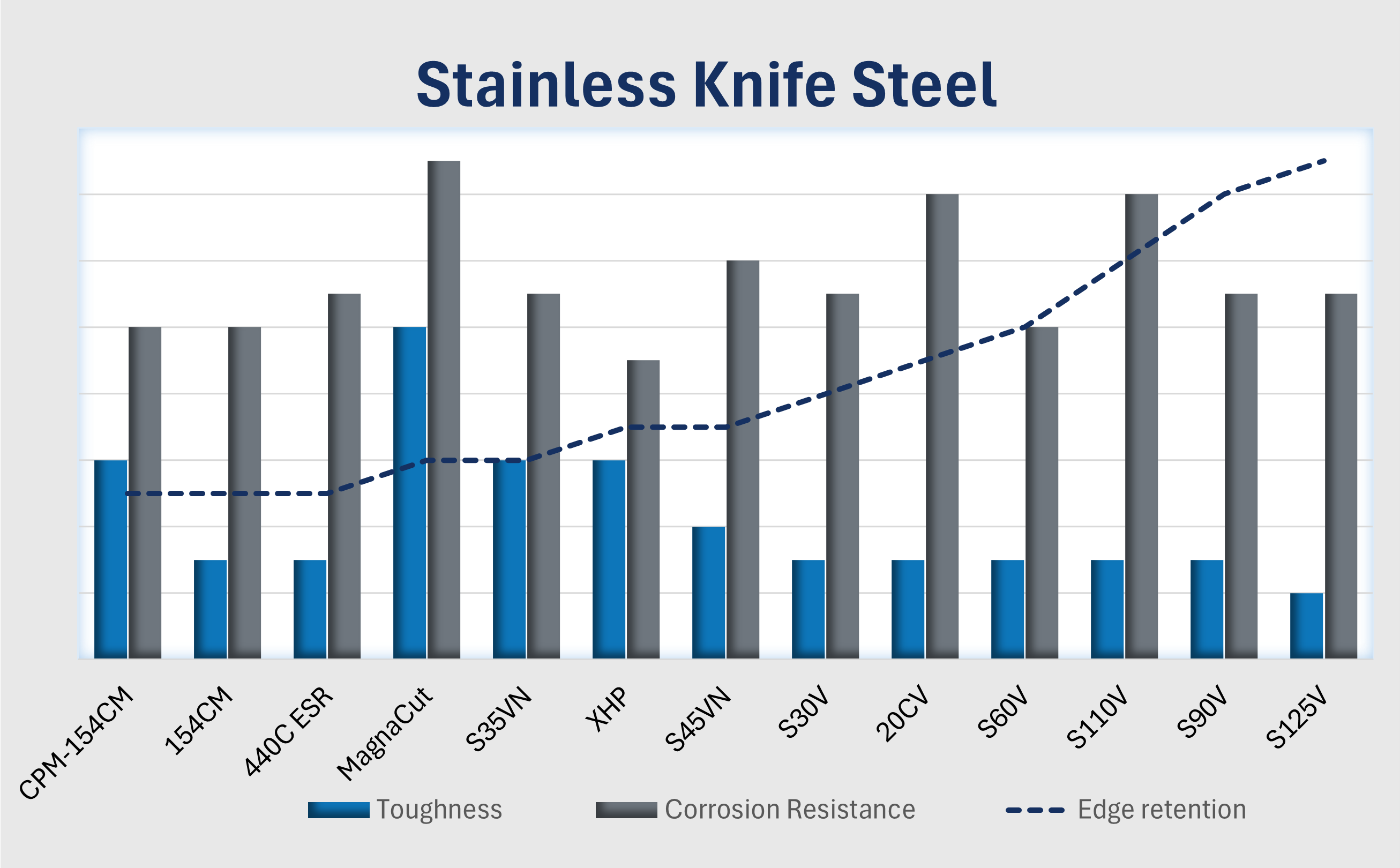

- MagnaCut®: A high-alloy stainless PM grade offering exceptional performance; MagnaCut® combines the corrosion resistance of stainless with the toughness of CPM® 4V.

As Niagara Specialty Metals continues to evolve with the industry, we remain committed to delivering best-in-class steel solutions through our fully integrated operations in Akron, NY. We are 100% employee-owned and handle all rolling, annealing, and finishing in-house to meet the highest standards of quality and performance.

| Grade | Category | Parts | Specifications |

|---|---|---|---|

| 416SS | Firearms | Slides for firearms, valves, shafts. Very machinable and good corrosion resistance. | ASTM A276 |

| 420SS | Medium Wear Stainless | Surgical instruments, scissors and various cutting tools. Good toughness and moderate corrosion resistance. | ASTM A276 |

| 440C ESR | Medium Wear Stainless | Food processing blades, Bearings and knife blades. High wear resistance and good corrosion resistance. | ASTM A276 |

| A2, H13, L6, O1, S1, and S7 | Air melted - Tough Tool Steels | Blanking dies, punches, shear blades, thread roll dies, chucks, pelletizer blades, plastic mold inserts | ASTM A681 |

| A7 Modified and D7 | High Wear Tool Steel | Brickmold liners, extrusion tools for ceramics, descale equipment liners | ASTM A681 |

| CPM® 1V, CPM® 3V, CPM® 4V, and NSM Wear | CPM® alloys that exhibit high toughness and heat resistance | Stamping & forming tools, dies, scrap choppers, fine blanking tools, planer blades coining dies | ASTM A681 |

| CPM® 9V, CPM® 10V, and CPM® 15V | CPM® Alloys that exhibit very high wear resistance | Pelletizer blades, barrel liners, punches, dies, granulator blades, slitter knives, screw tips, wear inserts | ASTM A681 |

| CPM® M4, CPM® T15, and CPM® Rex76 | CPM® high speed steels designed to cut other materials efficiently at high speeds despite the extreme heat generated at the tool's cutting edge. | Broaches, end mill, gear hobs, spade drills, taps, form tools | ASTM A600 |

| CPM® S30V, CPM® S35VN, CPM® S45VN, CPM® S90V, and CPM® MagnaCut® | Stainless Food Processing | CPM® alloys that have high wear and corrosion resistance well suited for industrial food processing. | |

| Greek Ascoloy | High Temp Stainless Steel | Steam turbine buckets, high temp bolts | AMS 5508 |

| M1, M2, M4, and M42 | High Speed Tool Steels | Punches, end mills, reamers, taps, tool bits, gear hobs, broaches | ASTM A600 |

| N155 | High Strength and Temp | High temp exhaust manifolds, turbine buckets, turbine blades | AMS 5532 |

| Super Invar | Low Expansion Alloy | Low expansion alloy used for structural supports for high precision optical and laser systems |

Stainless Steel

Many tooling applications require not only typical tool steel properties but also a degree of corrosion resistance. Our 400-series stainless steels meet these needs, as they are martensitic and can be hardened through heat treatment. While they do not offer the same level of corrosion resistance as 300-series stainless steels, they are much harder and more wear-resistant.

We sell six grades of wrought martensitic stainless steel and eight CPM® stainless grades. All of our steel is manufactured in the USA. Wrought stainless steels are used for blades and components in knives, the food and pulp industries, aerospace applications, valves, and numerous other critical applications.

416 is a free-machining stainless steel used primarily in applications that require extensive machining and corrosion resistance.

420 stainless is used in the hardened condition for shear blades and surgical equipment.

440C ESR and 154CM are used extensively for blade material. Our 440C is Electroslag Remelted (ESR) to create a higher-quality ingot. The ESR process removes impurities and inclusions through an additional melting step. 154CM is a slight upgrade to 440C with better wear and corrosion properties.

418, also known as Greek Ascoloy, is a heat-resisting martensitic stainless steel used in high-stress parts up to 1,200°F. Our 418 is ESR melted and capable of AMS 5616.

15-5 is a precipitation-hardening martensitic stainless steel with better toughness than 17-4 PH. Our 15-5 is VAR melted and capable of AMS 5862M.

Key Applications

- Knife blades

- Firearms

- Molds and mold inserts

- Certain plastic injection molding applications

Tool Steel

The performance of a metal forming tool relies on optimizing various factors. Typically, operating conditions such as applied loads, abrasive environments, and impact determine the tool’s durability. However, with numerous traditional and CPM® tool steels available, it is possible to select one with the right combination of properties for specific applications. Tool steels are categorized and compared based on properties that directly influence performance: hardness, toughness (impact resistance), and wear resistance. We sell a wide variety of tool steels in sheet, plate, and cut-to-size pieces.

The A series tool steels are characterized by their high hardenability, toughness, and dimensional stability in heat treatment. They can all be hardened by air cooling and are suited for cold-work applications.

All D series steels are resistant to softening at elevated temperatures. These steels also exhibit excellent wear resistance—especially D7, due to its high carbon and vanadium content. D-series tool steels contain 1.5 to 2.35 percent carbon and approximately 12 percent chromium, which contributes to the hardenability of these alloys. Typical applications for this class of steel include shear blades, brick molds, and slitter knives.

All S series steels are characterized by their toughness and resistance to shock. The principal alloying elements in S-series steels are manganese, silicon, chromium, tungsten, and molybdenum. Common applications for this group include chisels, punches, and fin-tube blades.

Miscellaneous grades include H13, L6, and O1 tool steels.

We carry several CPM® grades, which offer superior performance over wrought products. Alloy segregation is minimized, and the process produces a very fine microstructure. Cutting applications where edge toughness is required are improved significantly by the CPM® process because of the elimination of large carbides.

Please see our datasheet page for more details on the grades we carry and the related properties.

Key Applications

- Slitters

- Shear Blades

- Molds and mold inserts

- Blanking Tools

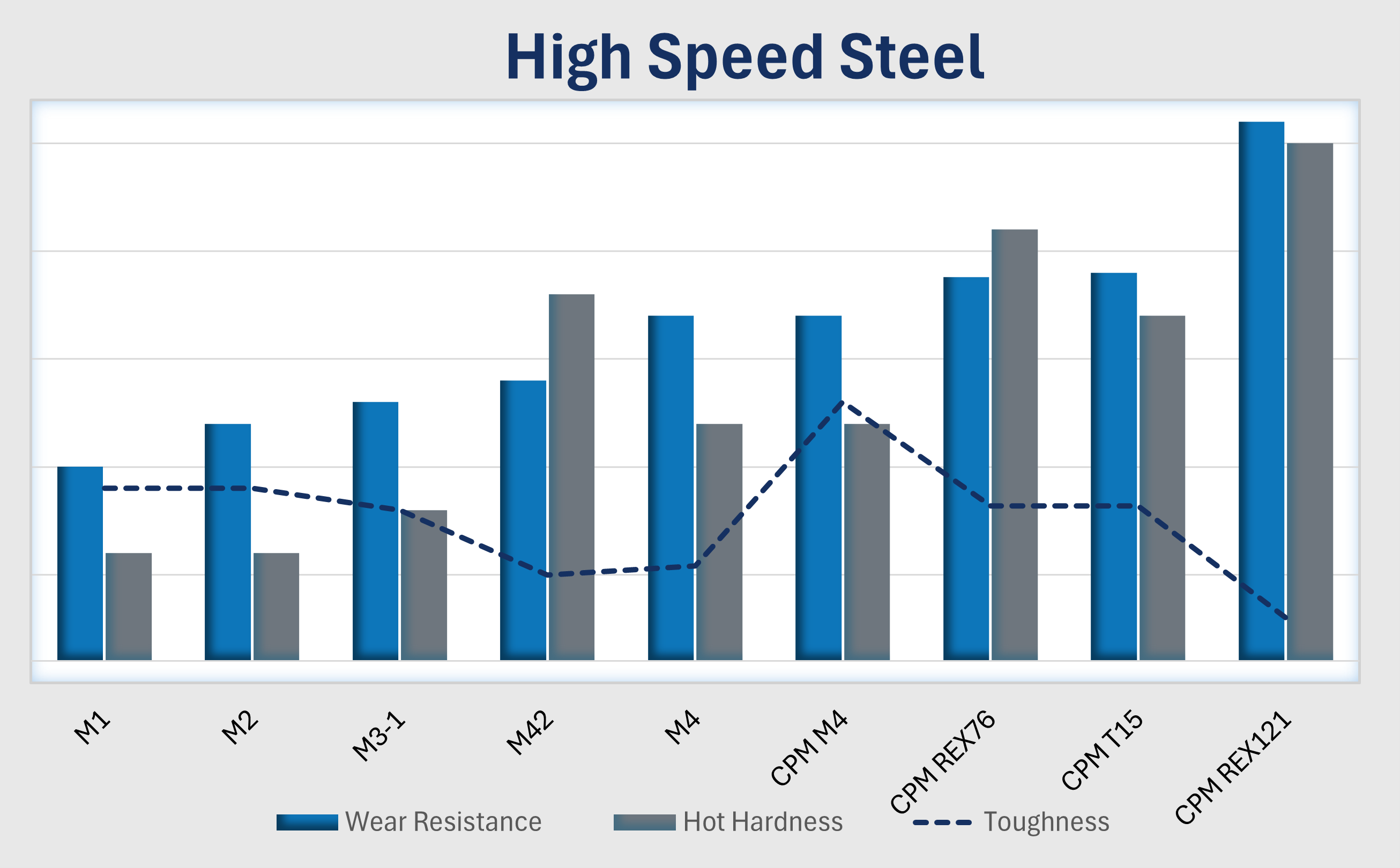

High-Speed Steel

High-speed steels (HSS) are high-alloy steels containing elements like tungsten (W), molybdenum (Mo), vanadium (V), and cobalt (Co). They are designed to cut other materials efficiently at high speeds, even when the tool’s cutting edge generates extreme heat, often exceeding 1,000°F depending on cutting conditions, coolants used, and other operational factors.

For good cutting tool performance, High-speed steel must possess three key characteristics:

1. High Hardness After Heat Treatment: HSS must be capable of being heat-treated to achieve high hardness at room temperature, typically ranging from 63 to 68 HRC. This high hardness is necessary for excellent wear resistance.

2. Red Hardness: HSS must maintain high hardness at elevated temperatures, a property known as red hardness. Since high-speed steels are exposed to significant heat at the cutting edge during operation, red hardness is essential for sustaining performance.

3. Impact Toughness: HSS must have sufficient impact toughness to handle interrupted cutting applications. They are significantly tougher than carbide or ceramic materials, which is crucial for withstanding the stresses of cutting.

Key Applications

- Broach Inserts

- Spade Drills

- Taps

- Dies

CPM® Process

Conventional high-alloy steels often develop alloy segregation during solidification. Even with extensive mill processing, clusters of coarse carbides persist as remnants of the as-cast microstructure, leading to non-uniform properties. This segregation can hinder tool fabrication, reduce toughness, and limit wear performance.

CPM® (Crucible Particle Metallurgy) steels avoid these problems by starting with tiny, rapidly solidified powder particles—each one having uniform chemistry and a finely dispersed carbide structure. These particles are consolidated through HIP (Hot Isostatic Pressing), ensuring the final steel contains no alloy segregation and features an extremely uniform distribution of fine carbides. This consistent microstructure resists grain growth, enhances toughness, and delivers superior wear resistance compared to conventionally produced steels.

Advantages of CPM®

For the End User:

- Availability of higher alloy grades

- Improved wear resistance

- Enhanced toughness (reduced chipping)

- Consistent tool performance

- Good grindability for resharpening

For the Tool Manufacturer:

- Consistent heat treatment response

- Predictable size changes during heat treatment

- Excellent and stable substrate for coatings

- Excellent grindability

- Improved machinability (with sulfur enhancement)

- Efficient wire EDM cutting