CPM® MagnaCut Stainless Steel vs. Other High-Performance Steels: A Detailed Comparison

May 23rd 2025

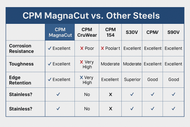

As the demand for high-performance blade steels continues to grow, CPM® MagnaCut stainless steel stands out as one of the most innovative options on the market. Whether you’re a knife manufacturer, metallurgist, or simply an enthusiast, understanding how MagnaCut compares to other top-tier steels like CruWear, 20CV, S30V, or CPM® 3V can help guide smarter material choices.

What is CPM® MagnaCut?

CPM® MagnaCut is a powdered metallurgy stainless steel developed by metallurgist Dr. Larrin Thomas in collaboration with Crucible Industries. It was designed to achieve an ideal balance of:

- Corrosion resistance comparable to stainless steels like 20CV and S45VN

- Toughness on par with tool steels like CPM® 4V or CruWear

- Edge retention rivaling that of premium wear-resistant steels

Its chemical composition minimizes chromium carbide formation, preserving chromium in solution to enhance rust resistance without compromising hardness or toughness.

Key attributes:

- High corrosion resistance

- Excellent edge retention

- Strong toughness

- Powder metallurgy construction for consistent microstructure

Applications for MagnaCut include high-end folding knives, outdoor survival blades, and EDC (Everyday Carry) tools where rust resistance and toughness are both priorities.

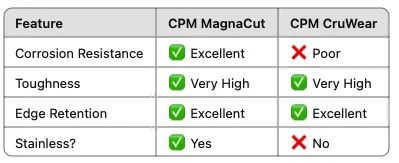

CPM® MagnaCut vs. CruWear

CruWear is a non-stainless tool steel known for its outstanding toughness and wear resistance. However, it lacks corrosion resistance, making it more prone to rust in humid or wet environments.

Verdict: MagnaCut offers all the toughness of CruWear with the added advantage of being stainless—making it a better choice for outdoor or marine environments.

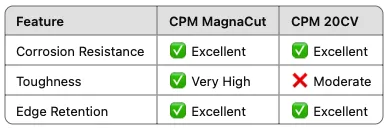

CPM® MagnaCut vs. CPM® 20CV

20CV is a premium stainless steel often used in high-end knives. It has great wear resistance and corrosion resistance but falls short in toughness.

When it comes to premium stainless steels, CPM® 20CV has long been a top-tier choice among knife makers and tool manufacturers, celebrated for its exceptional edge retention and corrosion resistance. But with the introduction of CPM® MagnaCut, the steel landscape has changed. MagnaCut challenges 20CV with a more balanced performance profile—especially when it comes to toughness and real-world utility.

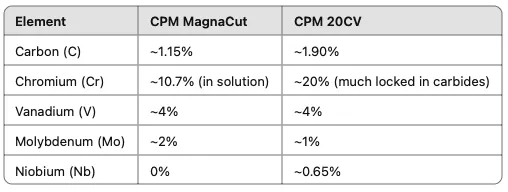

Composition & Metallurgical Differences

CPM® 20CV (similar to Bohler M390 and CTS-204P) is a high vanadium stainless steel with high carbon and chromium. Its microstructure includes hard vanadium and chromium carbides, which deliver great edge retention—but they can reduce toughness.

CPM® MagnaCut was engineered to avoid large carbide formation and instead maximizes chromium in solution, preserving stainless performance while enhancing toughness through microstructural control.

Performance Analysis

Edge Retention:

20CV retains its edge for a long time due to high vanadium and chromium carbides. However, MagnaCut delivers similar edge life, especially in real-world slicing and utility applications.

Toughness:

This is where MagnaCut shines. 20CV is known to be relatively brittle and prone to chipping under lateral stress. MagnaCut provides a significantly tougher matrix, reducing the risk of breakage during impact or aggressive cutting.

Corrosion Resistance:

Both steels offer top-tier corrosion resistance, but MagnaCut’s optimized chromium solution delivers slightly better performance in salt spray and humid conditions.

Ease of Sharpening:

CPM® 20CV is notoriously difficult to sharpen due to its wear resistance. MagnaCut, while still a high-performance steel, is noticeably easier to maintain with standard sharpening tools.

Applications & Use Cases

CPM® 20CV is ideal for:

-

High-end EDC knives where edge retention is the top priority

-

Kitchen cutlery and precision tools

-

Users who don’t frequently sharpen or maintain blades

Verdict:

If you prioritize absolute edge retention and operate in lower-stress environments, CPM® 20CV remains a solid option. However, for users who want a balanced combination of corrosion resistance, edge retention, and high toughness, CPM® MagnaCut offers more flexibility and real-world resilience.

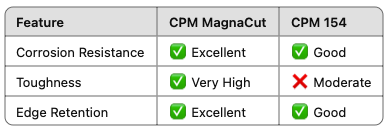

CPM® MagnaCut vs. CPM® 154

CPM® 154 is a martensitic stainless steel with good corrosion resistance and edge retention, often used in kitchen and EDC knives.

Verdict: CPM® MagnaCut surpasses CPM® 154 in toughness and overall performance, making it a stronger candidate for demanding environments.

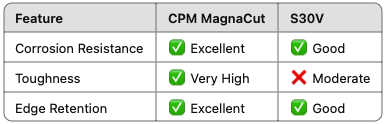

CPM® MagnaCut vs. S30V

S30V has long been a go-to steel for premium knives. It balances edge retention and corrosion resistance, but it is outperformed by newer steels.

Verdict: S30V remains solid, but MagnaCut is an evolution with improved toughness and edge stability.

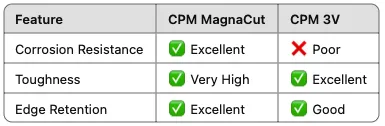

CPM® MagnaCut vs. CPM® 3V

3V is renowned for its toughness, often used in impact-prone tools and fixed blades. However, it is not stainless.

When toughness is the top priority, CPM® 3V is often the go-to choice. Known for its incredible resistance to chipping and breaking, CPM® 3V has long been a staple for fixed blades, bushcraft knives, and heavy-duty outdoor tools. However, CPM® MagnaCut introduces a new level of versatility by combining high toughness with true stainless steel performance—something CPM® 3V simply doesn’t offer.

Chemical Composition & Metallurgy

CPM® 3V is a high-vanadium tool steel developed by Crucible Industries, engineered to offer superior impact toughness. However, it contains little to no chromium in solution, meaning it’s not stainless and will rust without proper maintenance.

CPM® MagnaCut, on the other hand, uses a balanced mix of carbon, nitrogen, vanadium, and chromium, carefully optimized to maintain stainless properties while eliminating large chromium carbides. This means more chromium stays in solution to fight corrosion, all without sacrificing hardness or durability.

Performance Comparison

Toughness

CPM® 3V is still the gold standard when it comes to raw impact toughness—especially for applications involving batoning, chopping, or lateral stress. However, CPM® MagnaCut is not far behind and provides exceptional toughness by stainless steel standards, even rivaling many tool steels.

Corrosion Resistance

This is where MagnaCut clearly outperforms. CPM® 3V will oxidize and pit in high-humidity or marine environments unless coated or regularly oiled. MagnaCut remains rust-resistant even after exposure to sweat, moisture, and salty conditions.

Edge Retention

Both steels offer excellent edge retention, but CPM® MagnaCut generally holds an edge longer under slicing and abrasive use, thanks to a harder matrix and higher vanadium content forming harder vanadium carbides.

Sharpening & Maintenance

-

CPM® 3V is relatively easy to sharpen but needs frequent maintenance to prevent corrosion.

-

CPM® MagnaCut is slightly more wear-resistant, so sharpening may take longer, but you’ll sharpen less often, and rust will not be an issue.

Ideal Applications

CPM® 3V:

-

Survival knives

-

Choppers and machetes

-

Bushcraft knives for harsh, dry environments

-

Tools where rust is a lesser concern

Verdict:

If your use-case involves frequent exposure to moisture, sweat, or salt—and you still need high toughness—CPM® MagnaCut is the better all-around choice. For maximum impact toughness in controlled environments (or if rust isn’t a concern), CPM® 3V still has the edge.

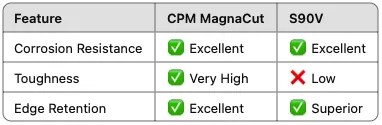

CPM® MagnaCut vs. S90V

S90V is one of the hardest steels available with exceptional edge retention. Its downside? Brittleness and difficulty sharpening.

Verdict: If pure edge retention is your only priority, S90V wins. But MagnaCut provides a better all-around package, especially for real-world durability.

Is CPM® MagnaCut the Right Choice?

CPM® MagnaCut stainless steel redefines what’s possible in high-performance knife materials. It competes directly with the best steels across multiple dimensions—edge retention, toughness, corrosion resistance—and rarely compromises.

For most modern applications, particularly those requiring all-weather or high-wear use, MagnaCut delivers a near-ideal solution. Whether you’re producing survival knives, EDC tools, or corrosion-resistant blades, CPM® MagnaCut is engineered for excellence.