Powder Metallurgy Steel Is Changing the Knife Game

Aug 7th 2025

Today’s best knives rely on a secret weapon, powder metallurgy steel. At Niagara Specialty Metals, we help knife makers build better blades with steel that’s cleaner, stronger, and more consistent. Whether you’re crafting a kitchen knife or a survival tool, PM steel gives you a better result every time.

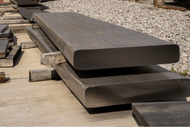

So what makes powder metallurgy steel so special? It starts with how it’s made. Instead of pouring molten steel into big molds, it’s atomized into fine powders, which are then heated and hot isostatic pressed to form clean, uniform slabs.

How Niagara Supports Knife Makers

- Rolling the Unrollable: Some steels are tough to work with, but Niagara knows how to handle even the trickiest grades. We take big slabs and turn them into thin sheets perfect for knives.

- Keeping PM Steels Alive: When Crucible went bankrupt, many worried about the future of powder metallurgy steel. Niagara stepped up. We worked with Erasteel and Carpenter Technology to continue supplying key grades like MagnaCut, S35VN, CTS XHP and S90V.

- Ready When You Are: Small shop or big business, we’ve got your back. Need cut blanks? We can laser-cut them from powder metallurgy steel sheets. Want a full plate? No problem.

Niagara’s commitment to quality doesn’t stop at rolling. Once a new powder metallurgy steel heat comes in, our team jumps into action cutting, testing, and processing it right away.

Bob Shabala also emphasized that while some PM grades like 15V may be discontinued due to technical limitations, Niagara is still able to carry almost all other popular grades by working with multiple suppliers.

Even our cutting equipment has evolved. We now have 2-axis bandsaws and a fiber optic laser that utilizes high pressure nitrogen to minimize any heat affected zone, making it easier to offer blanks in the exact shapes and sizes makers request.

Why PM Steel Wins Every Time

- Stronger Edges: Holds a sharp edge longer than regular steel.

- Rust Resistance: Stainless PM grades like MagnaCut resist corrosion, even in wet or humid places.

- Less Chipping: PM steel is tough and less likely to chip or break.

- Easier to Sharpen: Holds an edge, but still easy to maintain with basic tools.

Niagara Specialty Metals: Your PM Steel Partner

From MagnaCut to MagnaMax, Niagara keeps powder metallurgy steel available, affordable, and American-manufactured. We’re not just a supplier, we’re part of the knife community.

Looking to learn more about powder metallurgy steel innovation? Check out some of our related blogs here:

Powder Metallurgy vs Conventional Steel: What's the Difference?

Powder Metallurgy Steel is Changing the Knife Game

For more information, check out our other blogs.

Click here to view our product catalog at our updated e-commerce store!

Interested in additional information on powder metallurgy steel? Click here!