Erasteel Powder Metallurgy Steels: A Global Leader in Clean Steel

Dec 30th 2025

A New Era in Clean Steel

When you work with advanced materials, consistency isn’t optional, it’s essential. That’s why Erasteel powder metallurgy steels have become the global standard for innovation, precision, and reliability. For more than 50 years, Erasteel has led the world in powder metallurgy technology, pioneering cleaner, tougher, and more uniform steels trusted by the knife, aerospace, and tooling industries.

Erasteel’s story is one of continuous improvement. From its origins as a metallurgy innovator in Sweden and its global sales and distribution network today, every breakthrough is rooted in the same mission: to produce cleaner steels that perform flawlessly, no matter the challenge.

“Erasteel has more than 50 years of experience in powder metallurgy,” says Viktor Sehlstedt, Customer Technical Support Manager. “We’ve always focused on improving product quality and performance while exploring new markets like knife steels.”

The Legacy of Innovation

The foundation of Erasteel powder metallurgy steels was built on a simple but powerful idea: eliminate impurities, refine microstructure, and enhance performance at every step of production. By pioneering powder atomization and advanced melting techniques, Erasteel helped shape the future of high-performance alloys alongside other industry leaders.

This legacy continues today through cutting-edge research and technical collaboration with global partners like Niagara Specialty Metals, who roll, finish, and distribute Erasteel steels for customers across North America. Together, they ensure each piece of steel meets the highest standards for quality and consistency.

Inside the Powder Metallurgy Advantage

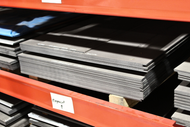

The science behind Erasteel powder metallurgy steels is all about control. Control over purity, carbides, and structure. Traditional steelmaking can result in uneven grain distribution and trapped inclusions. Erasteel’s process begins with atomizing molten steel into fine, uniform powder, then compacting it under extreme pressure and temperature.

The result?

- Cleaner steel with virtually no segregation.

- Uniform carbide distribution for exceptional edge retention and wear resistance.

- Superior toughness for demanding applications like knives, dies, and high-speed cutting tools.

As Bob Skibitski, Erasteel’s U.S. Technical Support Manager, explains:

“The chemistry on paper may be the same, but the fundamentals of the steelmaking process are different. Erasteel’s state-of-the-art equipment delivers higher cleanliness and consistency than ever before.”

Built for High-Performance Applications

Erasteel’s powder metallurgy steels are engineered for industries where performance failure isn’t an option. Whether you’re designing precision knives, aircraft parts, or industrial dies, the difference lies in predictability.

Knife makers appreciate steels like MagnaCut, S35VN, and CPM 154 for their toughness, corrosion resistance, and fine finish.

With Erasteel and Niagara working together, these materials are not just available, they’re optimized for your process, ensuring reliable results with every order.

Sustainability and Stewardship

Innovation isn’t just about performance, it’s also about responsibility. Erasteel integrates sustainability into every step of its operations. Modern facilities in Söderfors, Sweden, use advanced filtration and melting techniques to minimize waste and energy consumption while maintaining the highest metallurgical standards.

Each advancement in Erasteel powder metallurgy steels brings cleaner production, more efficient use of resources, and longer product lifespans; reducing environmental impact for manufacturers and end users alike.

The Future of Clean Steel

As industries evolve, so does Erasteel’s vision. New grades like MagnaMax and continued refinement of PM processes are shaping what comes next in the world of specialty steels. With Niagara Specialty Metals as a strategic partner, North American customers can expect faster delivery, consistent quality, and the same excellence Erasteel has maintained for decades.

When you choose Erasteel powder metallurgy steels, you’re not just choosing a material, you’re choosing precision, purity, and partnership that stands the test of time.

Looking to learn more about powder metallurgy steel innovation? Check out some of our related blogs here:

Erasteel Powder Metallurgy Innovation: Meet Viktor Sehlstedt

Powder Metallurgy vs Conventional Steel: What's the Difference?

Powder Metallurgy Steel is Changing the Knife Game

For more information, check out our other blogs.

Click here to view our product catalog at our updated e-commerce store!

Interested in additional information on knife steel or CPM® MagnaCut stainless steels? Click here!